FEATURED ARTICLES

Industrial Refrigeration

April 19, 2024

Bassett Associates Utilize Oculus to Showcase Ammonia Refrigeration System Through Virtual Reality at IIAR Conference

Industrial Refrigeration

April 16, 2024

Why Use Ammonia as a Refrigerant?

Industrial Refrigeration

April 12, 2024

Safeguarding Operations: The Crucial Role of 24/7 Ammonia Response Capabilities

Metal Fabrication

April 10, 2024

Driving Innovation: The Importance of Investing in Manufacturing Infrastructure

Industrial Refrigeration

March 19, 2024

EPA Finalizes Safer Communities by Chemical Accident Prevention Rule

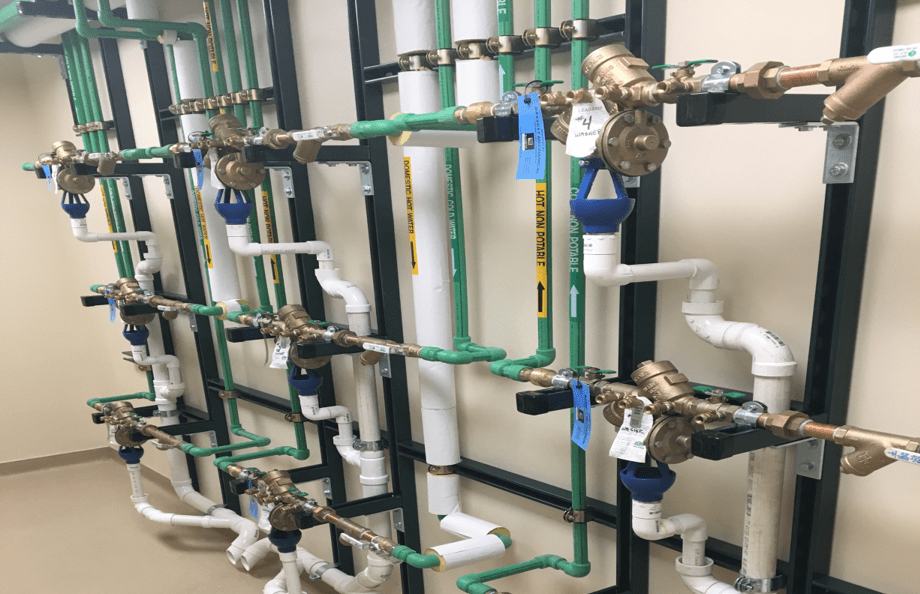

Plumbing

December 29, 2023

You received a notification that you must complete a cross-connection survey; now what?

General

December 29, 2023

2024: Embracing the Future Together! A Message to Our Valued Customers from Kim Bassett, CEO

Metal Fabrication

August 31, 2023

Mastering the Art of Pressure Vessel Fabrication: Ensuring Safety and Reliability

Industrial Refrigeration

August 29, 2023

A Comprehensive Guide to Industrial Ammonia Refrigeration System Components for the Food and Beverage Industry

Industrial Refrigeration

August 28, 2023

Understanding the Mechanics of an Ammonia Refrigeration System

Careers

August 10, 2023

Bassett Mechanical Youth Apprentice, Carter, featured in the Milwaukee Journal Sentinel

Careers

August 8, 2023

From Intern to Refrigeration Engineer: The Significance of Career Pathing for Interns