Bassett Mechanical specializes in customized industrial refrigeration systems and components to fit the individual needs and applications of a variety of production facilities. Although each design and recommendation is customized, many of these systems will require the fabrication of vessels to support the overall refrigeration system. The journey of these systems is vastly different than most as these vessel components are not outsourced, but crafted on-site in Kaukauna, Wisconsin where the design and engineering of the overall system is already taking place. This offering eliminates waste and creates higher quality application-specific solutions and accelerated delivery for customers. As one of the few refrigeration contractors in the United States to manufacture their own vessels, the story of how these systems are created is a unique one to tell.

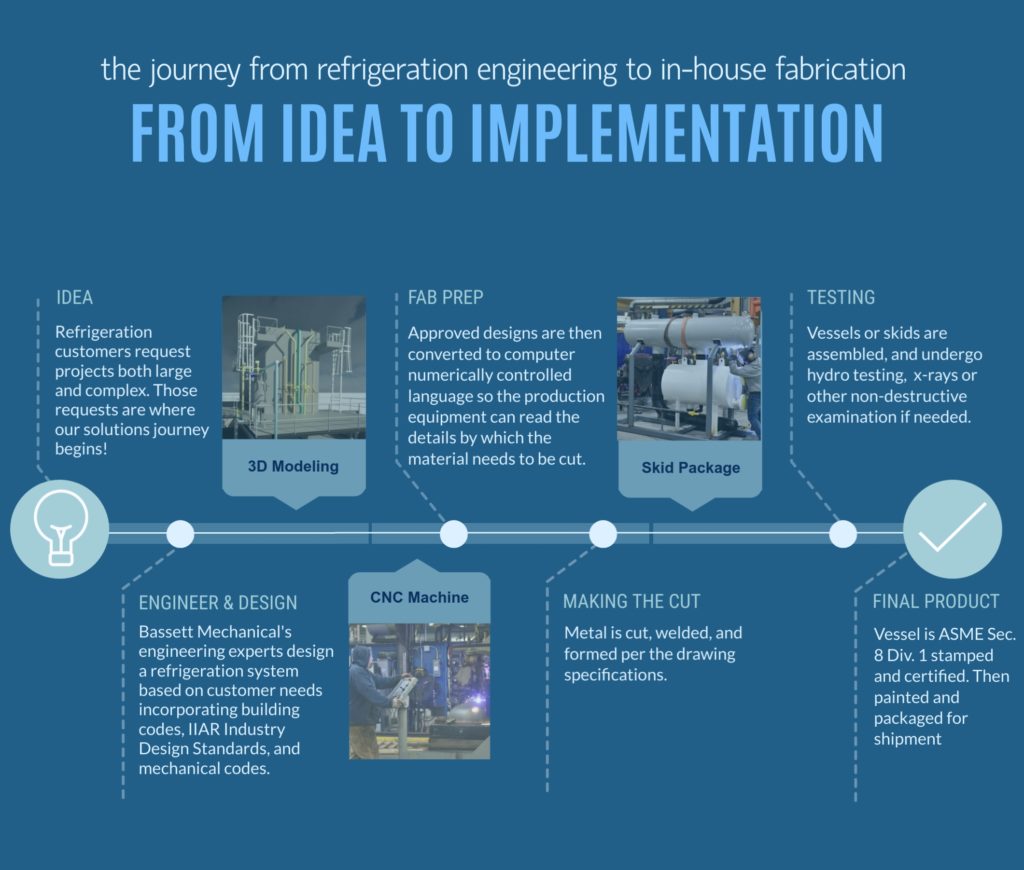

IDEA

The original idea for an industrial refrigeration system is based directly on the customer’s application, requirements, and needs. Customers may request a brand new system for a greenfield facility, while others request a replacement system or an addition to an existing system. Engineering teams seek to understand the application of the new system, the product being produced, and the specs necessary to generate a safe, optimal, and efficient design.

DESIGN

Once the specifications of the idea have been defined, the engineering teams get to work to generate a system design which generally includes several pressure vessels. Vessel design and 3D modeling of the skid assemblies is now in process. Required vessel design information may include details such as operating pressure, critical dimensions, net positive suction head, and nozzles. The design must also incorporate building codes, industry design standards (IIAR), and mechanical codes. Customers take advantage of Bassett’s expert peer review process to ensure the best possible solution is presented. The design is then reviewed, adjusted, and finalized with the customer so it can begin the initial stages of the fabrication process.

FAB PREP

An approved 3D model and design is then converted to computer numerically controlled language so the CNC cutting machine can easily read the details by which each piece of material needs to be cut. Preparation is done to ensure all specific materials required by the system are onsite and prepared for the project. Prepping this fabrication in-house allows Bassett to inventory common-sized ASME pressure vessel heads and frequently used materials to accelerate project completion and delivery time.

MAKING THE CUT

CNC machines are used in this application to cut pieces as needed. These machines provide an automated process for cutting and beveling, creating a pristine cut which provides for a better fit-up and in turn, a better weld. Metal is cut, welded, and formed according to the drawings and standards created during the design phase. If a plate is used, it will require precision cuts be made from the plasma cutter and will be roll formed up to 14 ft. in diameter. These vessels are crucial to the overall refrigeration system so the integrity of the cuts and welds are paramount to the longevity of the system and health and safety of our customer’s people and product.

TESTING

Due to the nature and usage of these vessels, each are ASME certified. This means that upon assembly completion, they are tested, which may include x-ray, ultrasonic testing, mag particle, or other testing as required by the design specification. After passing these tests, the vessels go through the final phase of NDT (nondestructive testing), the hydro test. Finally, after all testing is complete, the ASME Inspector issues the vessel a national board number to confirm it has passed all required test criteria for the design and is now considered an ASME Section 8 Division 1 Certified Pressure Vessel. Testing is a vital part of this process and customers find value in the ability to verify the integrity of these intricate parts of their systems.

FINAL PRODUCT

When the vessel has been certified and testing is complete, it goes through the final piece of its journey through the manufacturing facility. Depending on customer requirements and application, the vessel may go through the in-house blasting and paint process to meet drawing specifications. From there it is prepped for shipment to the job site where it will become part of the overall refrigeration system.

Vessels are just one very crucial piece of the overall refrigeration system. From idea, to 3D drawing, to live vessel, these vital components are truly a real-life transformation. Completing this creation in-house means beginning to end focus on the design of each element to maximize quality, safety, reliability, and effectiveness of each refrigeration system.

Bassett produces over 600 of these vessels every year. If you’d like to see this transformation in action, take our virtual facility tour or contact us to schedule a visit!