On September 23, 2017 the new OSHA (Occupational Safety and Health Administration) Silica Law went into effect. This standard requires that all employees must be protected from inhaling respirable crystalline silica. Silica is a compound that is found in things such as concrete, stone, mortar, glass, and sand. It is made airborne on job sites by tasks such as cutting, grinding, drilling/coring, and breaking these materials.

According to OSHA, these new rules are meant to limit the exposure of workers to crystalline silica and in doing so minimize their risk of developing diseases associated with repeated exposure such as: lung cancer, silicosis, chronic obstruction pulmonary disease, and kidney disease.

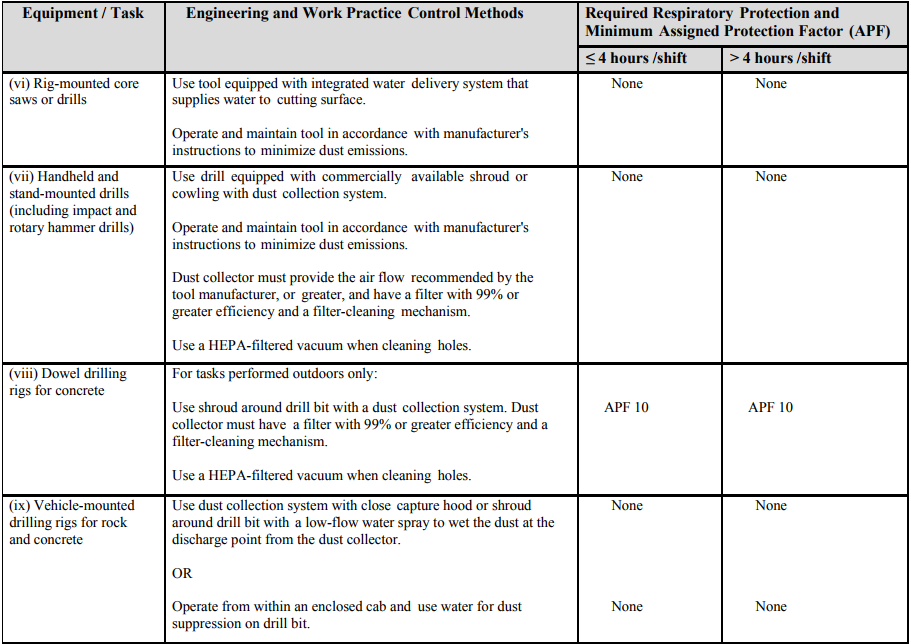

Moving forward, contractors must evaluate their procedures and work environments to ensure that they do not over-expose any of their employees to respirable silica. The preferred method to control exposure is to follow directives that OSHA has laid out on “Table 1”. Table 1 is a chart that shows common silica dust creating tasks and the proper control methods for each task. The control methods usually consist of using specially designed tools that have water jets or dust collection systems incorporated into them. An example of Table 1 is shown below and a complete table can be found on OSHA’s website.

Communication is important and habits are difficult to change, so ensuring that your teams are aware of the new procedures and are putting them into practice is crucial for their health and safety. Workers should be reminded to wear dust masks, vacuum with HEPA filter versus sweeping, avoid blowing the dust, practice consistent use of dust collection systems, and when possible wet down work to minimize airborne dust and particles.

OSHA provides opportunities for educational events and compliance assistance to employers looking for more information. For more information visit: https://www.osha.gov/silica/.