Well-designed buildings, systems, and control strategies can improve comfort levels, increase reliability, and reduce costs. With a combined HVAC/PLC controls solution, you can seamlessly connect all your data with one central tool combining everything from the plant floor to the office.

HVAC vs. PLC

HVAC stands for Heating, Ventilation, and Air Conditioning. An HVAC control system provides a 360° view of your building’s entire HVAC operation. It’s everything you need to maintain comfort for occupants, optimize energy usage, and identify and resolve problems in a timely manner.

PLC stands for Programmable Logic Controller. Industrial controllers are used to control different electromechanical processes for use in manufacturing, plants, or other automation environments. PLCs are widely used in a variety of industries including food and beverage, cold storage, and process and production because they’re fast, easy to operate, and are considered easy to program.

Learn more about PLC and HVAC Control Solutions

CENTRALIZED INFORMATION. SMARTER RESULTS.

Having both HVAC and PLC controls consolidated under one software platform can be important when trying to build sequences of operations to make a building “smart.”

Smart buildings are characterized by the use of wholly integrated systems, that control and share vital information about the building’s operations including heating, ventilation, air conditioning, lighting, security, and other systems. The benefits of smart buildings come from the data-generating systems that power them. It’s much easier to understand a building when there’s data to inform how people use them and it’s easier to manage a building when you understand them.

Smart building strategies can reduce energy costs, increase the productivity of the facility staff, improve building operations, support sustainability efforts, and enhance decision-making across the organization.

Is a combined HVAC/PLC controls solution right for your business? Here are 5 reasons why it could be:

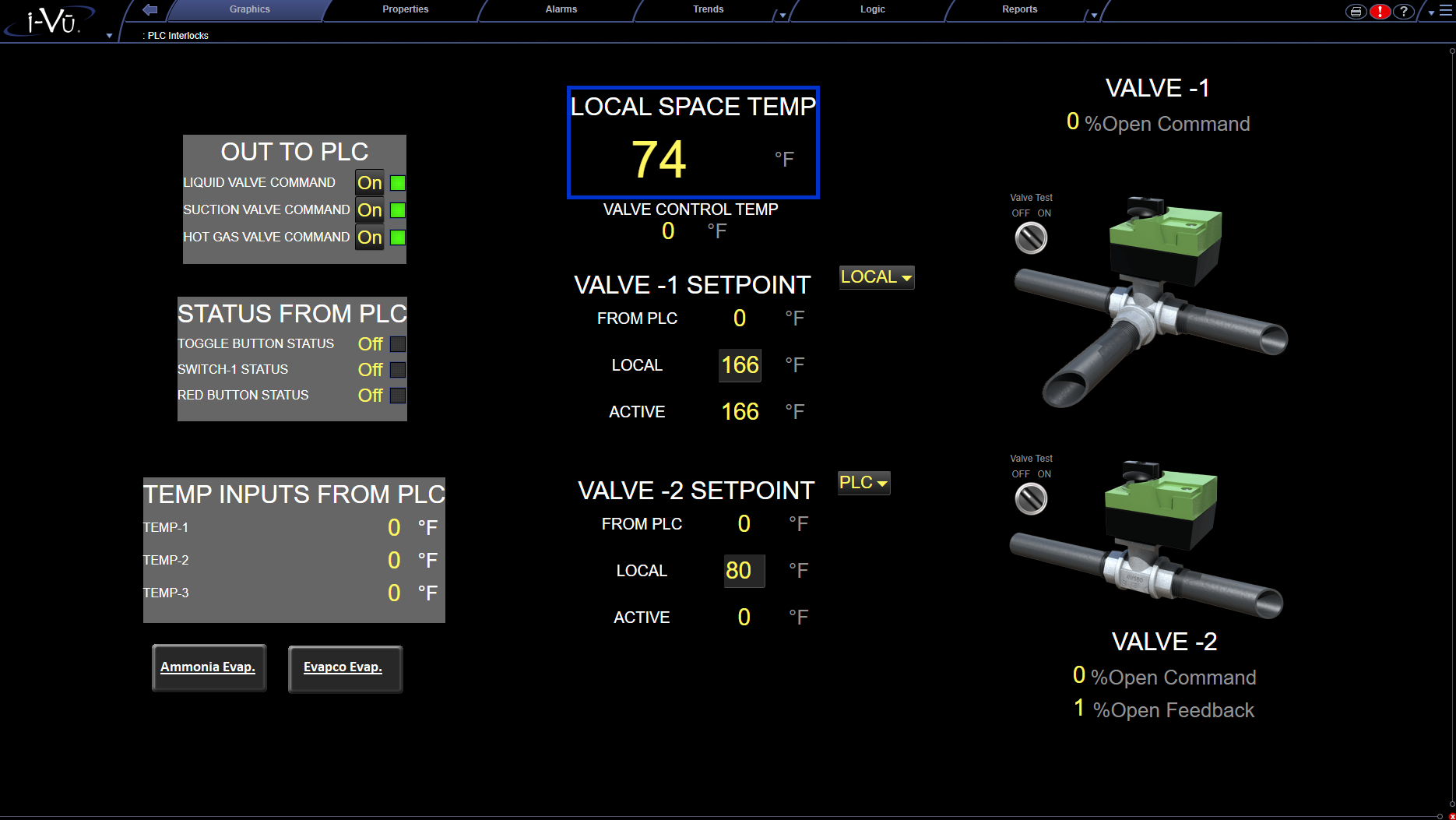

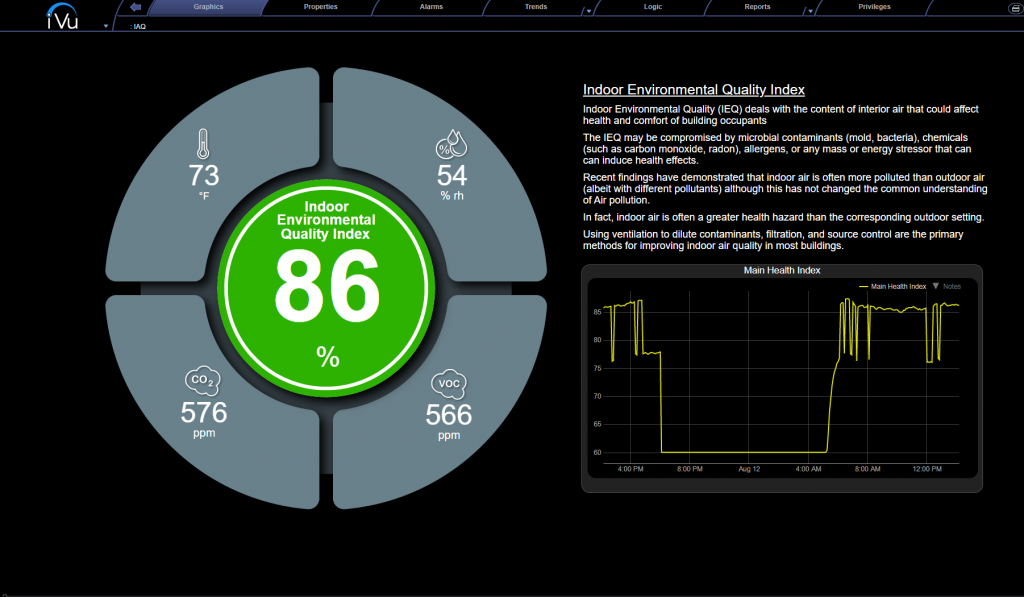

1) Customized Displays

With a combined offering, you can see and manage your entire system from one place with clear, accurate, real-time data and graphics. In one click, you’ll be able to monitor your production line, manage your refrigeration systems, and control the office temperature to ensure occupant comfort. Your system can be customized to show you the information you need daily instead of having to search through multiple systems to collect the information.

2) Data Sharing

Data access is a necessity. Business leaders want to be able to pull real-time data to manage operational efficiency and make informed decisions. With multiple systems, the operator must face the reality of not easily being able to see how each system is performing and how they integrate with each other.

Data sharing within a system is especially important in food facilities with ammonia. Ammonia refrigeration systems require additional safety requirements and data tracking. With an HVAC/PLC offering, the system can communicate crucial information including alerts – via email or text – that there could be an ammonia leak. As a result, the system will be able to shut down the unit with the leak while also communicating with the HVAC system to make any adjustments necessary to keep occupants safe.

A plant manager is also able to start and stop parts of the system, change the working parameters, and see the list of the current and past alarms.

3) Energy Efficiency

Automating the entire building instead of operating multiple standalone processes will improve overall energy efficiency.

The major areas of energy consumption in buildings are:

- HVAC (heating and cooling systems, ventilation, and air conditioning) – 35%

- Lighting – 11%

- Major appliances (water heating, refrigerators, and freezers, dryers) – 18%

- Miscellaneous areas including electronics – 36%

The Department of Energy says in each case there are opportunities both for improving the performance of system components and improving the way they are controlled as part of an integrated building systems management.

A combined offering will allow you to pull the data, study each process, and see where the highest energy costs are coming from. In return, engineers, building managers, or maintenance personnel, will be able to make note of any trends and adjust as needed resulting in future cost savings.

4) Save Time & Money

The management and maintenance of these systems can become complex for facility personnel. Utilizing a combined controls solution, you can maximize employees’ time by streamlining the data into one easy system.

A combined offering also cuts down on installation costs and lower maintenance costs by giving you greater insights into the health of the equipment and facility along with the effectiveness of your processes.

5) HVAC & PLC Controls Expertise

We work together with customers to create a system that is expandable and ready to grow as their company grows. The Bassett Mechanical controls team will assist with everything in-house from start to finish including programming, troubleshooting, and analyzing what system is best for the customer’s needs.

Because we work closely with our Industrial Refrigeration and HVAC designers and engineers, we have a unique perspective on integrating control systems customized to suit your refrigeration, HVAC system, or process requirements utilizing the most current technologies. That’s what sets us apart from other companies and offers our customers the customization and reliability they are looking for.

TIME TO UPGRADE

There will be considerable growth in building automation systems in the future, much of which can be attributed to the savings it affords building owners and operators in time and money.

Whether you are installing a new mechanical system, retrofitting, or re-calibrating an old one, our team of control experts can design a flexible, cost-effective control system based on your needs. Our experts provide on-site training and remote support to maximize your software experience and reduce costs related to service calls.

Call our control experts today to see if one universal platform is the right fit for your business.