At Bassett Mechanical, we’re committed to building a stronger future—both for our company and for the customers we serve. As part of that commitment, we’ve significantly expanded our pipe fabrication capacity and capabilities at our Kaukauna facility.

This strategic investment is driven by two key goals: supporting the growing volume of mechanical contracting projects and creating new opportunities by offering pipe fabrication services directly to our metal fabrication customers.

Enhancing Efficiency and Expanding Capacity

To achieve these goals, we’ve integrated several advanced pieces of equipment designed to improve workflow and optimize production space. In 2024, we introduced a new CNC plasma pipe profiler with an integrated material infeed/outfeed system, along with a new band saw and exterior conveyor system. These upgrades enable our team to safely and efficiently handle materials outside the facility and seamlessly route them into production for cutting and processing.

Watch our CNC plasma pipe profiler in action.

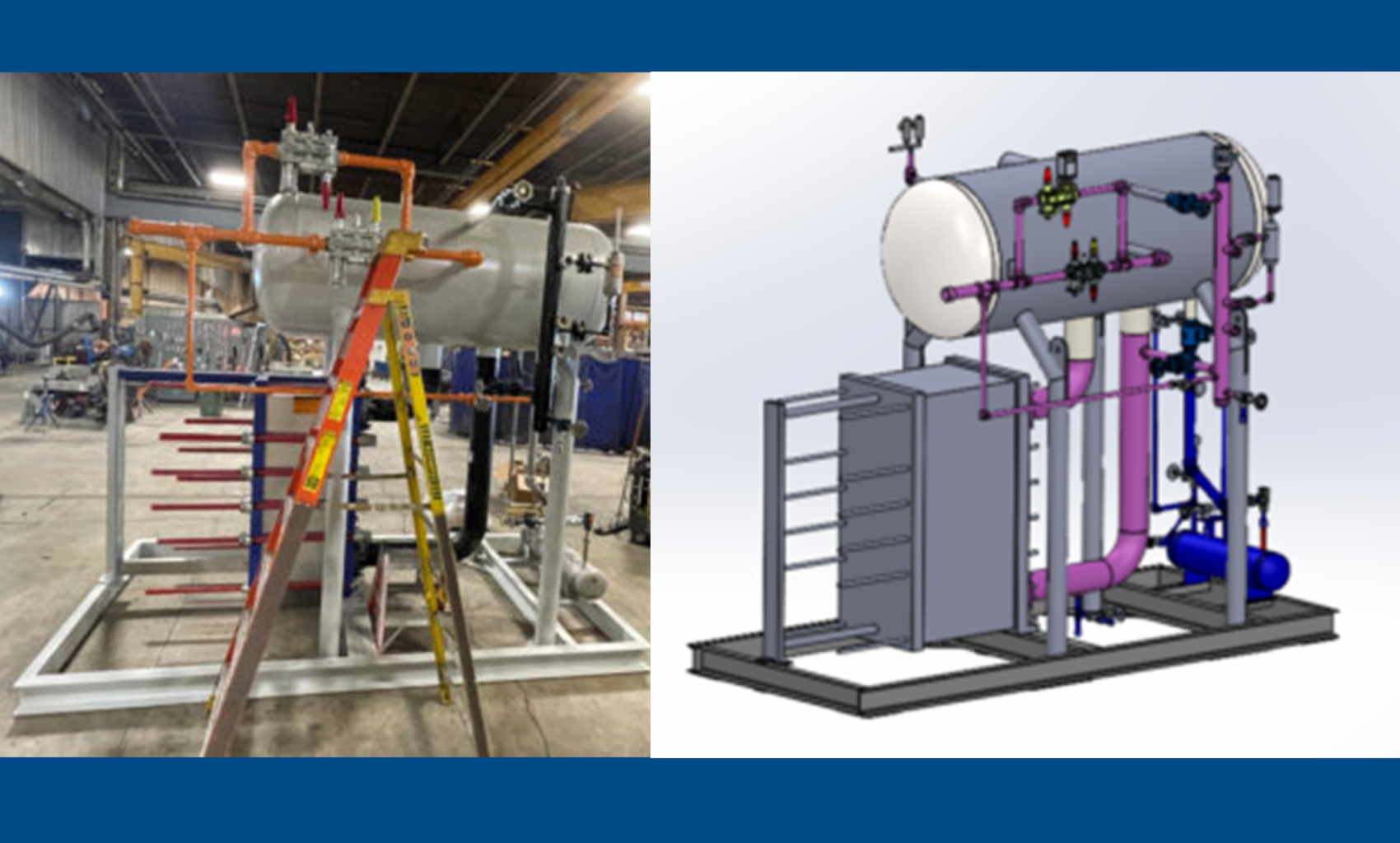

As part of our long-term strategy to establish Bassett Mechanical as a leader in fabrication solutions, we’ve expanded our production footprint by 10,000 square feet, specifically dedicated to enhancing our pipe fabrication capabilities. This additional space for pipe fabrication, staging, and loading is more than just added square footage—it’s a critical investment in our future. By incorporating new multi-process welding machines, weld positioners, tool boards, carts, and cranes, we’re equipping our skilled tradespeople with the tools they need to work efficiently, safely, and at scale. This expansion lays the groundwork for continued growth, enabling us to take on larger, more complex projects while maintaining the high standards our customers expect.

“Our strategy has been to move as many direct labor hours through the shop as possible without increasing indirect costs. By focusing on pipe fabrication, we’re improving consistency and reliability in our equipment usage—it’s also better for our workforce,” said Tyler Peterson, VP of Manufacturing.

Investing in People and Processes

Our growth isn’t just about equipment, it’s about people. We’ve added key roles across Business Development, Project Management, Project Foreman, Pipe Fabrication, and Quality Control to ensure we continue delivering successful projects. Our Virtual Design and Construction (VDC) team has also taken on expanded responsibilities, supporting project detailing, programming, and routing to the shop floor.

As part of our ongoing commitment to innovation, Bassett Mechanical transitioned to a fully electronic workflow across our fabrication operations. This shift enhances department communication, streamlines project tracking, and reduces reliance on paper-based processes. By integrating digital tools for scheduling, documentation, and quality control, we’re improving accuracy, accelerating turnaround times, and supporting a more sustainable workplace. Our teams can now access real-time project data from the shop floor to the front office, ensuring alignment, transparency, and responsiveness at every stage of production.

Delivering Value for Our Customers

These investments go beyond increasing capacity; they create a more consistent and reliable workload for our associates, maximize the use of our facility, and enhance our ability to deliver high-quality projects on time. By maintaining control over our fabrication environment, we’re better positioned to meet the demands of our mechanical contracting customers with precision and confidence.

At Bassett Mechanical, we’re not just growing, we’re building a future that’s smarter, stronger, and more capable than ever. Contact us to learn more about our capabilities.