Bassett Mechanical is pleased to offer this educational series to share industry updates and best practices for your facility operations in response to the recent COVID-19 pandemic.

We are committed to keeping you, an important member of our Bassett Mechanical Family, safe and are here to assist you in making informed and proactive decisions related to the quality and safety of your facility.

This series will explain how contaminants may impact your facility and your facility’s mechanical systems, potential strategies and risks to consider, and ways you can respond to help keep your people and products clean and safe.

The COVID-19 pandemic has made an impact on nearly every area of our lives. As facility owners and operations managers, you have seen these changes significantly impact your business and your people. Through it all, you accept great responsibility to make decisions that are in the best interest of your facility and associates. Among those decisions are important opportunities to ensure your facility is playing a proactive role in the safety of your associates and daily operations.

WHAT’S IN THE AIR?

The World Health Organization (WHO) indicates that “The COVID-19 virus spreads primarily through droplets”. Humans emit these droplets and smaller particles (also known as aerosols) into the air through coughing, sneezing, talking, and even breathing. Similarly, activities such as toilet flushing and some medical procedures can also emit particles into the air.

HOW ARE AIRBORNE PARTICLES TRANSMITTED?

The American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE), an organization that supports research that advances the knowledge base of indoor air management strategies to reduce occupant exposure to infectious aerosols, describes the airborne distribution of these droplets and particles in some of their most recent publications and position documents.

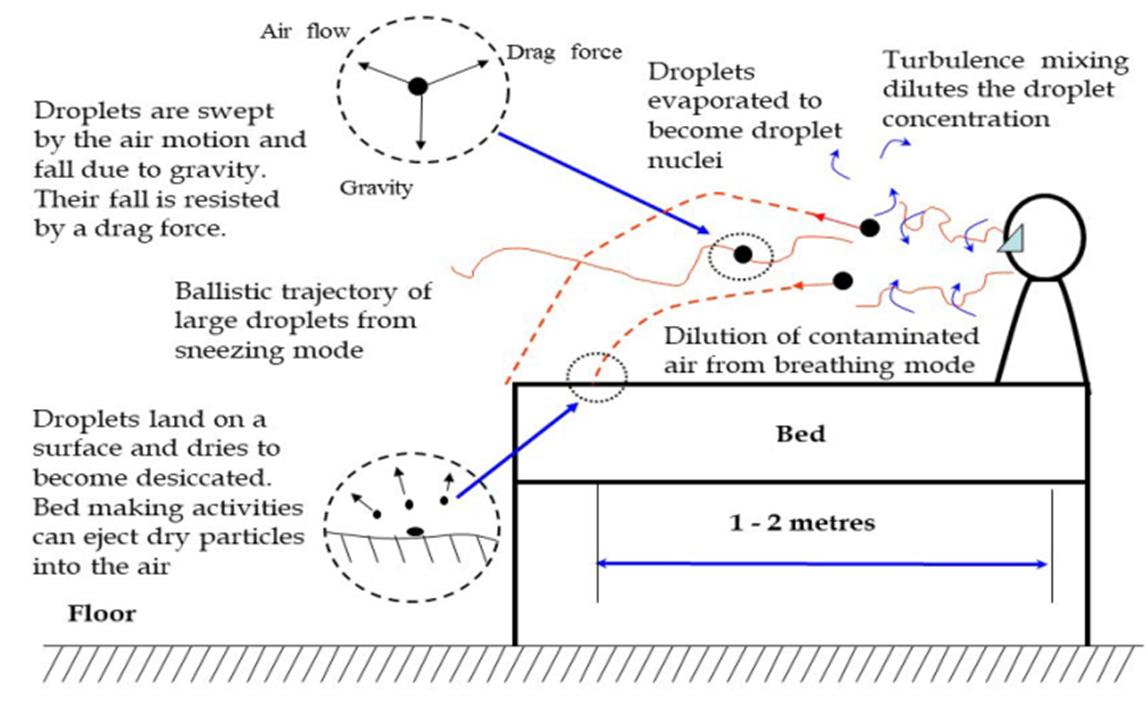

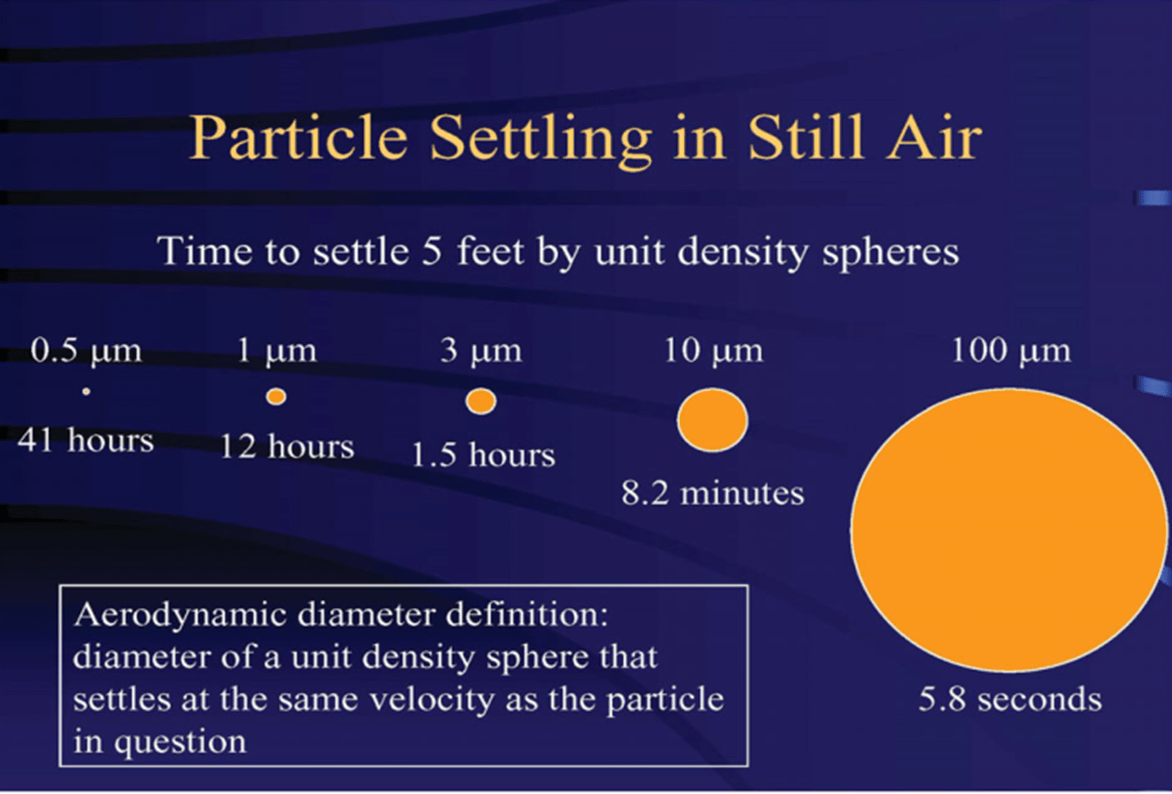

Research indicates that most large infectious droplets are drawn by gravity and land on surfaces within about 3-7 feet (1-2 m) from the source (see figure 1). Smaller aerosols (<10 µm), can stay both airborne and infectious for extended periods of time, even days. As a result, aerosols can travel prolonged distances and can transmit the infection to parties who had no contact with the primary source. Even larger droplets (100 µm diameter), depending on the environmental variables, may begin to evaporate becoming an aerosol (approximately <10 µm) before settling on surfaces or hosts.

HOW DOES MY HVAC SYSTEM IMPACT TRANSMISSION?

While data indicates dilution ventilation and pressure differentials do not significantly impact short-distance transmission, it can impact the distribution of smaller infectious aerosols through airflow patterns. Aerosol transmission can be directly influenced by directional airflow which can create clean-to-dirty flow patterns and move infectious particles through systems where they can be captured or exhausted.

POTENTIAL MITIGATION STRATEGIES FOR INDOOR AIR

These mitigation strategies are not applicable or suitable for every facility or mechanical system. Before implementing any changes it is important to contact your trusted and knowledgeable HVAC provider for guidance in evaluating which strategies may prove most successful for your facility’s specific needs.

Upgrade your filters. Consider upgrading your current filters to MERV-13 pleated filters. Standard filters like the MERV-8 pleated have a pressure drop of .26 while the MERV-13 pleated filter has a pressure drop of .37. Even with this minimal airflow difference, there should be confirmation that the filter upgrade will not affect the system performance.

Local exhaust ventilation for source control. Experts like Bassett Mechanical can help you explore options for a local exhaust ventilation system which can help reduce exposure to airborne contaminants including dust, mist, fume, vapor, or gas. This is a control measure to ensure contaminants are captured at the source and filtered or exhausted in a safe manner.

Evaluate your energy recovery ventilation systems. Some energy recovery ventilation systems pose a risk of leaking potentially contaminated exhaust air back into the indoor air supply. Contact Bassett Mechanical for options for evaluating and possibly bypassing this system as appropriate.

Temperature and humidity control with RH optimal at 50%. According to ASHRAE, scientific literature generally reflects the most unfavorable survival for microorganisms when the RH is between 40% and 60%. Controlling RH can reduce the transmission of certain airborne infectious organisms.

Keep systems running and increase outdoor air ventilation. Typically tenants save on energy costs by setting their HVAC systems to unoccupied setbacks during hours of vacancy (nights or weekends). HVAC systems that run 24/7 are working to filter out the airborne contaminants and can potentially provide cleaner air for your occupants. There may be options to allow an increase in outside air or 100% outside air to be used as a short term “purge”. Specific systems must be evaluated for capacity prior to increasing outside air.

To learn more about these strategies to support your indoor air quality and the effectiveness of your daily operations email us at info@bassettmechanical.com.