Imagine what the job site would be like today without construction technology. Today, new technologies in construction are developed at a rapid pace. A company’s choice to invest in and expand its virtual design and construction (VDC) capabilities is a significant financial decision accompanied by many positive impacts for the customer. Innovations in laser scanning are bringing a shift in the construction industry.

What is laser scanning?

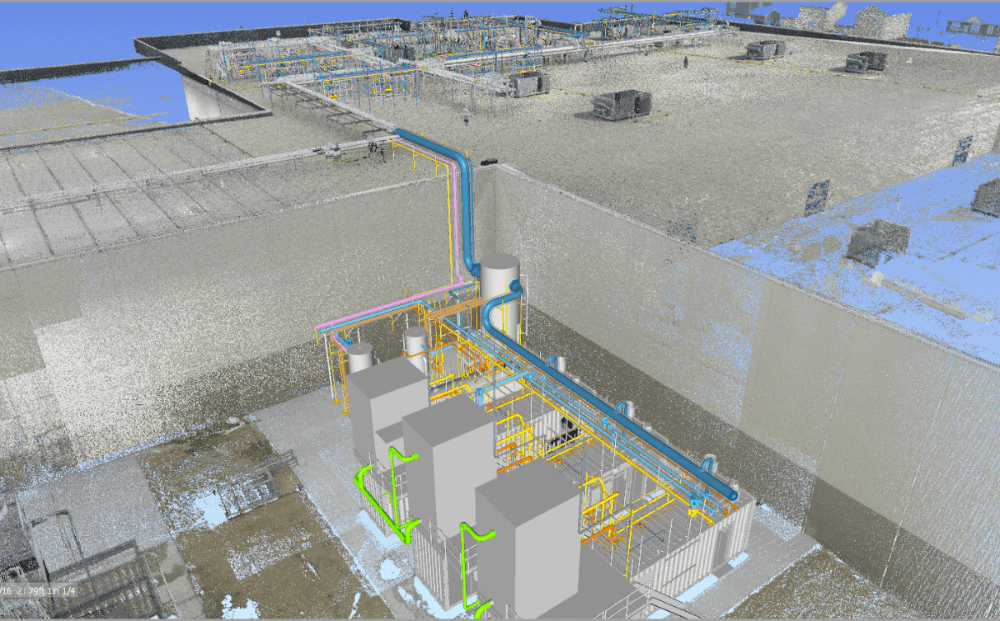

Laser scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. The scanners create point clouds and digital photos of the onsite conditions, helping with efficiency and productivity in the field and the office. Laser scanning can be used throughout the project’s life cycle in design, construction, operations, retrofits, and renovations.

Laser scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. The scanners create point clouds and digital photos of the onsite conditions, helping with efficiency and productivity in the field and the office. Laser scanning can be used throughout the project’s life cycle in design, construction, operations, retrofits, and renovations.

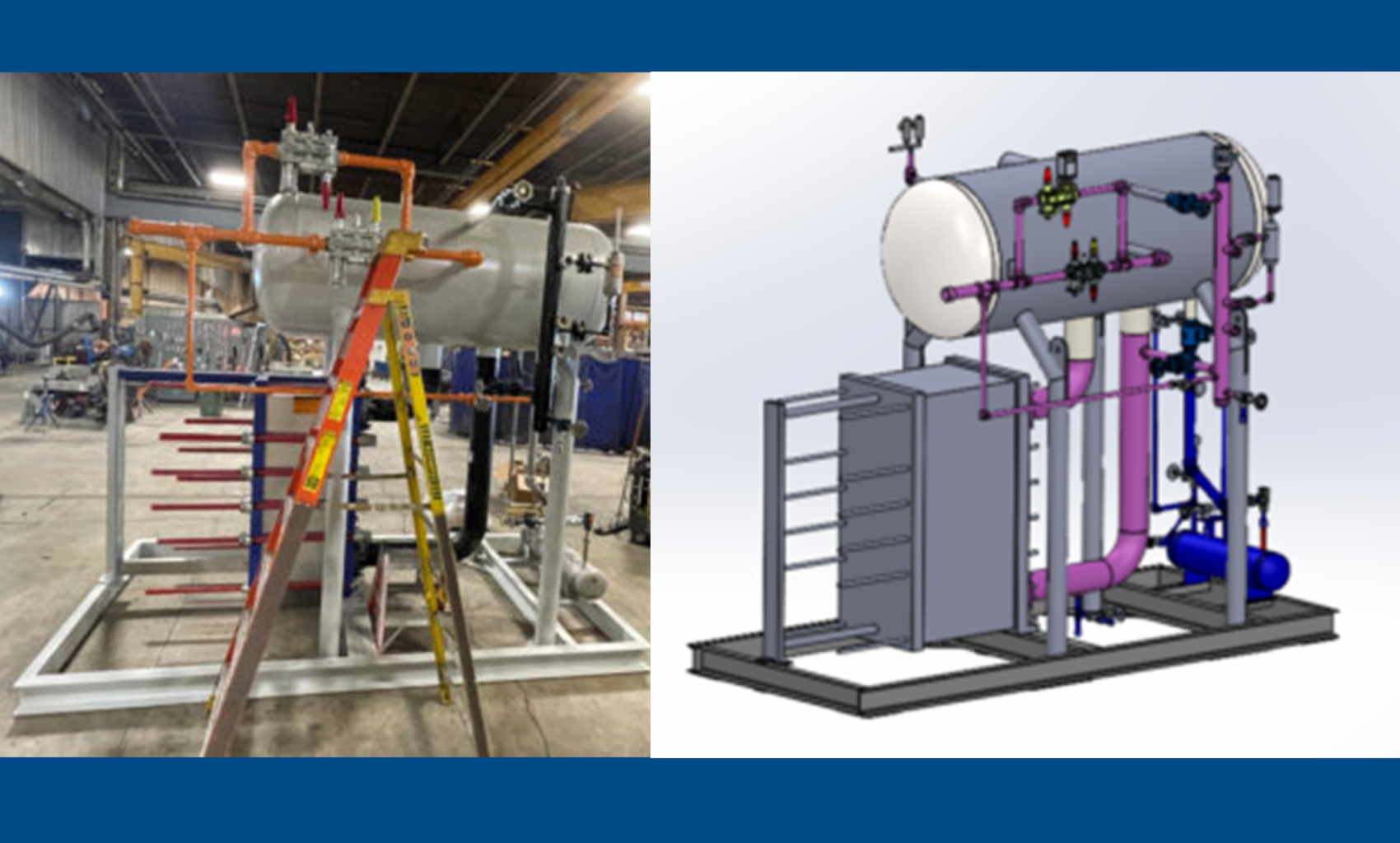

“When we first purchased a laser scanner, we knew that capturing the onsite field conditions at customer job sites, before starting the design of a project would provide us with information necessary to create a model we felt confident prefabricating from. A large majority of our work is retrofitting to existing conditions, so without the laser scanner, we would be missing out on being able to prefabricate to the same level as we do on new construction. It has helped us take our planning and detail for a project to the next level,” said Tyler P., Director of Prefabrication.

Laser scanning offers many advantages, making it an essential tool for numerous projects.

Improves accuracy and quality

On new construction, our teams can take the design up to 90% completion and wait until crucial pieces of equipment are set in place on-site, then scan that area and finalize the design, so the field teams don’t have to measure the final connections. We’ve also found that this works well in congested production areas.

Offer immediate information

Scans can be performed and accessed immediately, improving operations, streamlining productivity, and reducing rework.

Improves planning and design

Laser scanning improves planning as it provides you with exact measurements. We have scanned existing facilities so that our engineers could use the scan data to do load calculations rather than spending a week or more onsite physically measuring, taking notes and individual photos, and then coming back to the office to piece it all together.

Reduces schedule and cost

Rework accounts for 12 to 15 percent of the construction cost of a typical construction project. With laser scanning, catching conflicts before they happen can reduce rework to 1 to 3 percent or less. This reduction translates into hundreds of thousands of dollars in savings on change orders, not to mention the advantage of keeping the project on schedule.

“When we scan a customer site, instead of just scanning the area where work will be performed, and when job sites are a long distance from our home office, we will often spend an extra day or two to capture data from the entire facility. This saves our engineering teams time by being able to look at the scan data and photos of the facility from their desk when estimating other work without having to travel back out to the job site. This also provides us with data for future projects that would otherwise have to be done by physically traveling back to the job site and making sketches and notes,” said Petersen.

Provides better collaboration and coordination

Provides better collaboration and coordination

In an era of remote work and connectivity, teams may work together across states or even the country. Laser scans can create a 3D virtual site overview to access site details and complexities no matter where your team is. Architects, engineers, designers, and construction teams can collaborate on a single source.

Ensures worker safety

Worker safety is always a top priority and more important than anything else. Laser scanning reduces worker exposure and helps identify any hazards. Some representations can be produced in astonishing detail, which reduces the chances of inaccuracy because of human error.

Committed to Virtual Design and Construction

Laser scanning offers the expertise and technology that allows our teams to achieve things that we’ve never been able to do before. At Bassett Mechanical, we are constantly researching ways to provide more benefits to our customers. We are committed to utilizing these cutting-edge technologies with our extensive design and prefabrication capabilities to provide safe and high-quality solutions for our customers.

Are you interested in learning more about Pre-Construction technology? Click here!

Provides better collaboration and coordination

Provides better collaboration and coordination