Connecting. This is a term we use almost daily. From emailing to texting, from “friending” to “hashtagging”, we have become familiar with ways to connect ourselves to others and gather information. With our desire for instant information and the technology available to facilitate communication, Bassett is seizing the opportunity to change the way we approach the communications with our valued customers.

Connecting. This is a term we use almost daily. From emailing to texting, from “friending” to “hashtagging”, we have become familiar with ways to connect ourselves to others and gather information. With our desire for instant information and the technology available to facilitate communication, Bassett is seizing the opportunity to change the way we approach the communications with our valued customers.

Over the past few years, Bassett Mechanical has implemented the use of Webtech in our HVAC service area, a software tool that connects customers directly with details of the service being done on their equipment and taking the customer experience to a new level.

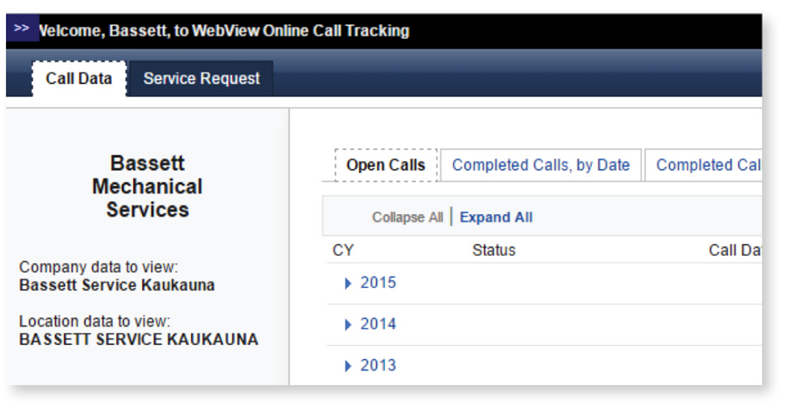

Webtech is a mobile field service tool that gathers customer and equipment information electronically so that is can be accessed 24/7 by any service technician at Bassett Mechanical. The connectivity to the secure customer web viewing portal also means that customers can instantly view their service reports and equipment information in real time providing them with the accessibility they need to manage their assets and predict potential budgetary needs.

The Webtech tool is available on the phone or tablet of any of Bassett’s HVAC service technicians. When a technician receives a call to help a customer, they can instantly access the details they need to provide safe and efficient service. The benefits of such a robust tool are numerous including:

- Safety. Through this tool, all technicians can see safety protocols and customer requirements for entering a facility or working on equipment at each particular facility location. If special training is necessary, technicians have this visibility ahead of time to ensure they are prepared for that facility’s specific needs and can streamline the process so that the equipment can be serviced as efficiently as possible.

- Documentation. Equipment information is laid out in intricate detail in the tool. Model numbers, serial numbers, amperage, voltage, and replacement part information are all at the technician’s fingertips. When Bassett is responsible for the installation of the equipment, photos and details are tracked immediately in the system upon setup, so even if the years have weathered the plates and part details on the equipment itself, technicians can use the system to easily and efficiently find the replacements needed and data required to accurately service the equipment.

- Response time. Webtech has the ability to provide addresses and GPS access to each individual customer location. If a customer places an emergency call and the on-call technician has not been to that facility before, he can quickly and easily use the GPS feature to get directions to the correct customer location, providing faster response time to customers when they have an urgent need.

- Status updates. The tool acts as the hub for all updates and system information. This prevents miscommunication between various parties and ensures there is minimal rework requested or required. If a customer requests an update on the status of a specific part, maintenance, or service needed, any technician (regardless of their familiarity with the plant) can pull the data from the system and work to get the customer the information they need. This Lean approach to handling customer requests minimizes rework and protects the investment the customer has made in their equipment.

- Completion notices and reports. Upon completion, the technician’s report of services provided is immediately available on the customer web viewing portal, which allows full visibility for customers to see what type of work has been done on each piece of equipment.

- Budgets and asset management. Because Webtech provides real-time information population into our customer web viewing portal, customers can log in anytime and see a list of their equipment as well as the history of services that have been performed. This allows customers to make budgetary plans related to replacement or updates of major pieces of equipment to avoid a complete malfunction or downtime.

- High-quality standards. During the routine preventative maintenance portion of the agreement, a technician uses this tool to access a complete checklist of maintenance tasks. This ensures that maintenance is completed consistently between all three service locations as well as between all skilled technicians so customers know that the same high-quality standards they expect will be met each and every time their equipment is serviced.

“The development of this tool within our company means that our technicians are highly prepared to offer the best service. They know what they need to get the job done” says Nick Hietpas, Bassett Mechanical Area HVAC Service Manager. Technicians are proud of the way this tool has streamlined their access to information and given them the opportunity to take their communications with the customer to new heights.

The service department is eager to roll out this new tool with the refrigeration teams in January of 2019. Completing this final phase of the rollout means that all service technicians will be on this mobile system by February 2019.

Roxanne Hoff, Business Systems Manager at Bassett says “this is just the beginning.” Bassett Mechanical has been integrated with the software platform and the program developers during the various phases of its creation. “We are still looking at enhancements, tweaks, and suggestions that could help take this already great software to the next level”. The team is looking forward to continuing to make developments that give customers the solutions and connections they need.

Want to know more? HVAC Service Customers who want to learn more about their existing web viewing capabilities can contact Lisa Knuppel at lisa.knuppel@bassettmechanical.com.