At Bassett Mechanical, innovation isn’t just a buzzword—it’s a commitment. Our adoption of MSuite has transformed our operations, from order entry to shipment, ushering in a new era of digital efficiency, precision, and productivity.

Impact of MSuite on Production

MSuite has redefined how we manage and execute projects in our fabrication shop. Here’s how it’s making a difference:

- Real-Time Job Visibility: Foremen and project managers can now track job progress digitally—anytime, anywhere. MSuite Fab provides the insights needed to stay on schedule and budget, from physical work completion to comparing estimated versus actual labor hours.

- Reduction in Paper Waste: Gone are the days of binders stuffed with drawings, travelers, and material tracking that get damaged during fabrication. MSuite Fab has nearly eliminated the need for printed drawings and job stickers, streamlining communication and reducing waste.

- Digital Time Tracking: Employees clock in and out through MSuite Fab, eliminating paper timesheets, making payroll processing efficient and accurate.

- Standardized Workflows and QC Integration: Built-in workflows guide fabricators through a consistent order of operations. Quality control (QC) and 3rd party or customer hold points are embedded in the system, allowing QC personnel to review and record approval of work directly from their iPads or computers.

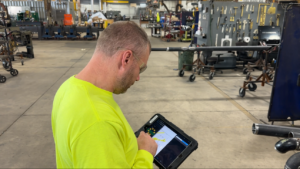

- Integrated Scheduling and Drawing Access: MSuite Fab connects with our other software platforms to power digital scheduling boards displayed on TVs throughout the shop. Operators can view upcoming projects, access digital drawings on their iPads, and begin work without needing printed documents or manual updates.

- Automated Cutting and Programming: MSuite Fab integrates with our cutting software, automating programming for pipe and structural components. It also receives real-time machine feedback to update cut status and track heat numbers.

- Simplified Shipping Coordination: A built-in shipping calendar allows easy scheduling, while MSuite Fab automatically generates Bills of Lading and packing lists.

“MSuite has completely changed the manufacturing game for us,” says Tyler P., VP of Manufacturing at Bassett Mechanical. “By digitizing our workflows and automating key processes, we’ve achieved levels of efficiency and accuracy that were previously unimaginable. It’s a transformative tool that has truly elevated our operations.”

Impact of MSuite on Project Documentation

MSuite Fab has revolutionized our documentation control processes by replacing time-consuming manual tasks with streamlined digital workflows. Here’s how:

- Digital Job Readiness Sorting: Previously, QC teams waited for physical binders containing signed drawings, calculations, and material requirements. Now, jobs are digitally sorted using a job log, allowing QC to identify and prioritize jobs.

- Paperless Travelers and Documentation: Travelers once had to be manually developed and printed, with each weld listed separately and hold points requiring handwritten initials. Today, travelers and related documents are uploaded and tracked directly in MSuite.

- Automated BOM and Heat Code Tracking: Heat codes were once tracked by snipping and printing BOMs. MSuite now tracks heat codes automatically, ensuring accuracy and eliminating the need to translate penmanship.

- Digital Inspection and Annotation: Final dimension drawings used to be printed and rubber-stamped for each inspection stage. Now, all final inspections are digitally annotated within MSuite, improving traceability and reducing paperwork.

- Streamlined NDE and Hydro Documentation: NDE reports, hydro test results, and other inspection documents were once printed, signed, and stored in physical folders. With MSuite, these documents are signed electronically and saved digitally, ensuring secure and accessible records.

- Centralized Document Storage: Previously, QC personnel had to scan and manually organize documents into network folders—drawings, calculations, BOMs, MTRs, U1A forms, nameplate photos, green tags, and more. Today, all documentation is uploaded to SharePoint directly from MSuite, eliminating scanning and manual sorting.

From Manual to Modern

Our journey from traditional methods to a fully digital workflow has been nothing short of revolutionary:

- Digital Everything: From drawings and schedules to timecards and QC documentation, our entire workflow is now digital, reducing errors and increasing efficiency.

- Automated Fabrication Tools: Our CNC Angle Clipper, CNC Structural Profiler, CNC Pipe Profiler, and back gauge on our Marvel saw—integrated with cutting software such as Procam and PypeServer—allow for direct export of cutting files from design files, automating cutting, punching, and layout tasks that were once programmed manually.

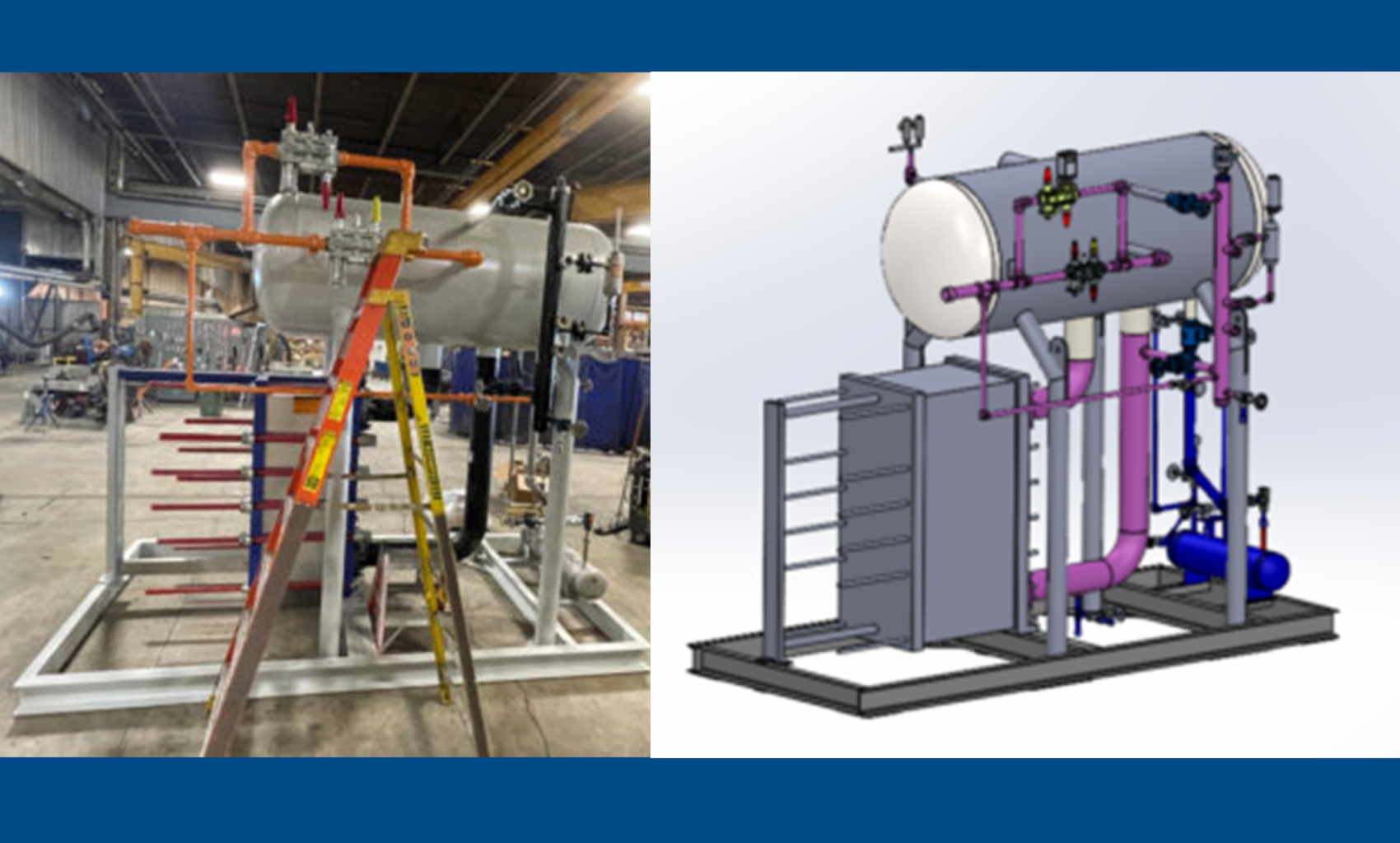

- Software Synergy: MSuite BIM, a plugin to our design software (Revit) and SpoolFab, generates spool drawings that integrate seamlessly with MSuite Fab and our CNC cutting software. On the vessel side, SolidWorks models are exported to our isometric spool drawing software SpoolFab, eliminating manual take-offs, and can be directly imported to our fabrication tracking software MSuite Fab.

Leading the Industry with Digital Excellence

Utilizing MSuite’s two products, Fab and BIM, has empowered Bassett Mechanical to lead confidently in a competitive industry. By embracing digital tools and automation, we’ve not only improved our internal processes but also enhanced the quality, speed, and reliability of the products we deliver to our customers. We’re not just building equipment—we’re building the future of fabrication. Contact us to learn more.