Bassett Mechanical has served our customers with various industrial refrigeration solutions, so we understand all the factors involved when choosing a refrigerant. Frequently, the preferred refrigerant for large industrial applications has proven to be ammonia, though the customer’s specific needs are always jointly evaluated.

Here are some factors to consider when choosing a refrigerant for your industrial refrigeration needs.

Regulatory Changes Regarding HFCs

Today, there has been a flurry of activity in the US regarding the phasedown of HFCs (synthetic refrigerant type), the growth in applications for carbon dioxide (CO2 – another natural refrigerant), and the introduction of HFOs (another synthetic refrigerant type), and HFC/HFO blends.

The US recently joined over 140 other countries and the European Union in ratifying the Kigali Amendment, targeted at the phasedown of HFCs to reduce global warming. This follows the prior phasedown of CFCs and HCFCs (the first synthetic refrigerants) to prevent damage to the Earth’s protective ozone layer. Man-made refrigerants have a history of undesired environmental consequences.

Natural Refrigerant Choices

With the impending phasedown of HFC refrigerants, which are typically applied to small/medium-sized refrigeration systems, four HFC replacement paths appear to be developing:

- One option is a CO2-based refrigeration system, a natural refrigerant choice.

- Another option is broadening the application of ammonia systems to meet smaller requirements, another natural refrigerant choice.

- A third option is the application of HFOs, the new synthetic refrigerant, which brings flammability and new environmental concerns to be aware of.

- The fourth is a blend of the HFCs (being removed from the market) and HFOs, which eliminates the flammability concerns of the pure HFOs but retains the environmental concerns associated with HFCs.

CO2 – Another Natural Choice

CO2 is a straightforward, future-proof choice, and it is one for which manufacturers continually develop an array of improvements, enabling its broad application. Manufacturers and system designers appreciate that CO2 is environmentally sound and, therefore, safe from needing to be phased down in the future.

CO2 is a straightforward, future-proof choice, and it is one for which manufacturers continually develop an array of improvements, enabling its broad application. Manufacturers and system designers appreciate that CO2 is environmentally sound and, therefore, safe from needing to be phased down in the future.

CO2 has its own nuances and design hurdles. It operates at high pressures and when at elevated outdoor temperatures; unlike other refrigerants, it exists in a state (supercritical fluid) that is relatively new to system designers and technicians.

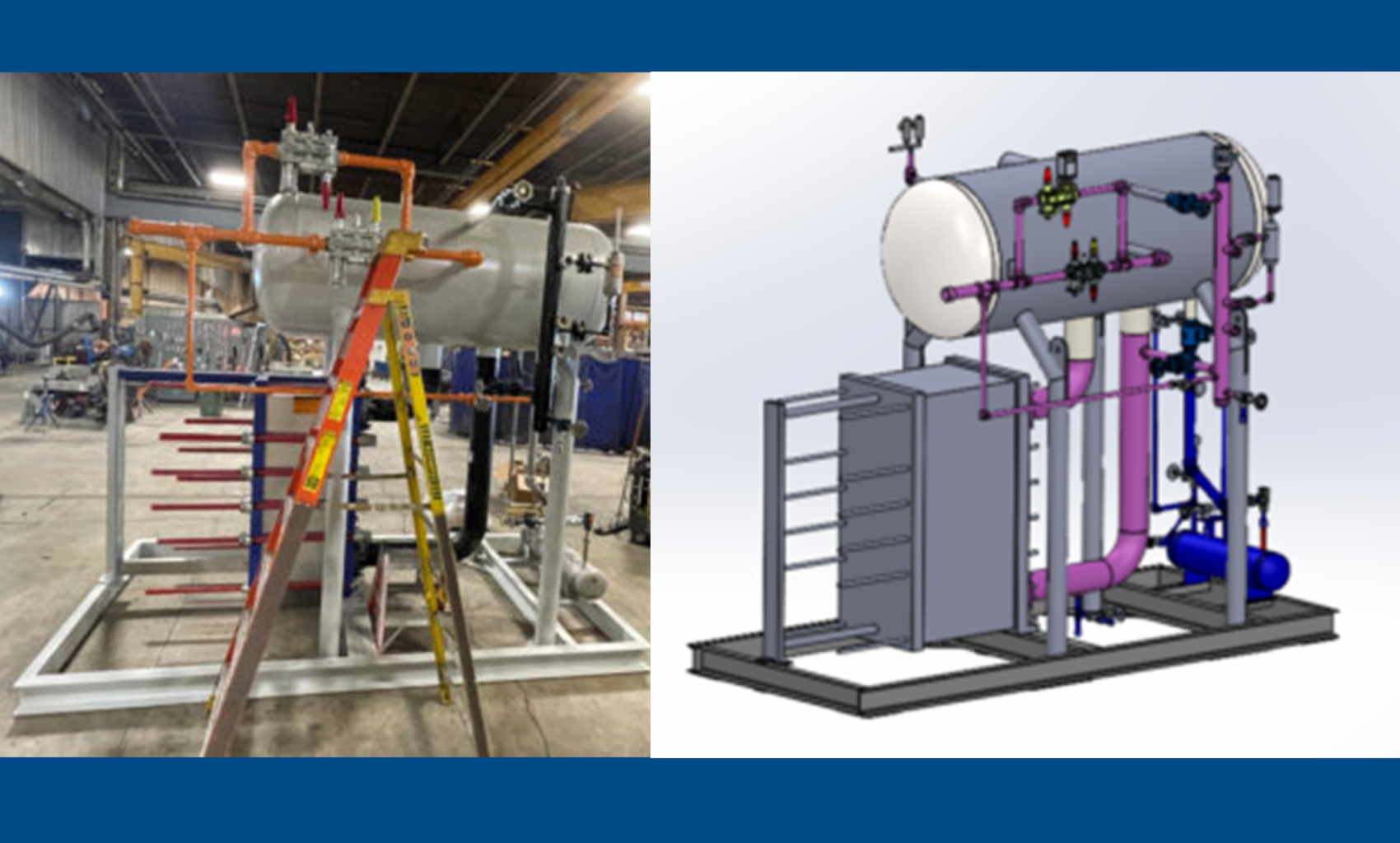

Bassett has successfully installed CO2 systems and has an upcoming customer project to install a 600-ton CO2 refrigeration system for process cooling. We can attest to the ability and experience of solid engineering and safe practices to overcome the design hurdles associated with CO2.

Synthetic Alternatives

Alternatively, in refrigeration applications, HFO/HFC blends reduce, but don’t eliminate, the environmental consequences for which HFCs are being phased out. Due to blending, the quantity of HFCs are reduced but are still there.

Like past synthetic refrigerant developments, there appear to be uncertain environmental consequences associated with HFOs. That, along with HFO flammability concerns and system efficiencies available with ammonia and CO2, make natural refrigerants a preferred choice for refrigeration systems.

Regulatory Deadlines Impacting Your Choice

In concert with and before the US approval of the Kigali Amendment, the AIM Act was passed by Congress and signed into law in December 2020. This Act directs the EPA to phase down the production and consumption of HFC refrigerants and to assist the transition to new refrigeration technologies, moving away from HFCs.

Regarding production and consumption caps, the phasedown schedule for HFCs requires levels to be reduced by 40% from baseline by 2024 and 85% from baseline by 2036. These reductions will reduce these synthetic refrigerants’ supply, increasing their prices. Furthermore, manufacturers and designers will be directing their development efforts elsewhere.

Manufacturers will be left with fewer choices. As mentioned, the EPA has been directed to assist in transitioning to new technologies. They are accomplishing this by applying sector-based restrictions. For example, in the EPA’s proposed rule, by January 1st, 2025, the EPA will prohibit manufacturing or importing products, for industrial process systems, with refrigerant charge capacities of > 200 lbs., with refrigerant GWPs (global warming potential) greater than 150. That GWP limit eliminates R404a or its synthetic replacements (R448a, R449a, R452a, or R134a) from consideration.

The impactful consequences of separate GWP restrictions and the effective dates of January 1, 2025, have been detailed by the EPA for cold storage warehouse and ice rink applications, among others.

Choosing a Refrigeration Solution That Sets You Up for Long-Term Success

With our customers’ businesses focused on their production and not necessarily refrigerants, Bassett Mechanical is a great resource to help you sort through refrigerant changes, regulatory implications, best choices, phasedown timelines, and opportunities.

When making your next refrigeration equipment or system decision, Bassett Mechanical is ready to be your partner with an 87-year history of design/build, and service refrigeration knowledge and experience. Contact us if you need assistance choosing a long-term solution for your refrigeration needs.