Why a Comprehensive Service Range, Certified Welders, Responsiveness, and Capacity Matter

Whether you’re executing a project in the marine, paper and plastics, healthcare, energy, water treatment, or food and beverage industries, searching for the right pipe fabricator can be complicated. Read on to learn what to look for in a pipe fabricator.

Look for a full range of capabilities

Your project is unique, and the right pipe-fitting professionals will be able to support any need you have. Their broad service range should enable unique and proprietary designs and robust customization.

Here are some offerings to keep an eye out for as you shop for pipe fabricators:

- Certified in-house talent, including Engineers, Project Managers, Certified Welding Inspectors, and Detailers

- A state-of-the-art facility with a controlled, safe space for projects of any size

- Advanced CNC plasma and laser cutting capabilities

- Rolling and forming capabilities

- ASME weld certifications in a wide range of different materials and welding procedures

- In-house blasting and painting

- Advanced 2D and 3D CAD and isometric pipe spooling software

- In-house testing experience, including visual, magnetic, dye penetrant, ferrite, hardness, hydrostatic, pneumatic, PMI, phased array, and ultrasonic testing, as well as third-party radiography

- Additional services to support your business, such as budgeting, shipping, and project status tracking

Prioritize fabricators with welding certifications and a quality system you can trust

Accuracy and precision are essential to your project, and the right pipe fabricator will have relevant certifications to instill confidence and ensure your pipe assemblies are done right—the first time.

Look for a collaborator with these qualifications to limit delays, waste, rework, accidents, and unnecessary future maintenance:

- ISO 9001:2015 Certification

- United Association of Journeymen and Apprentices of the Plumbing and Pipefitting Industry of the United States and Canada (UA) skilled employees

- American Society of Mechanical Engineers (ASME) weld certifications in accordance with ASME section IX

- Affiliations with National Certified Pipe Welding Bureau (NCPWB) and Pipe Fabrication Institute (PFI)

- American Welding Society (AWS) certified welding inspectors

In addition to certifications, your partner should be equipped to tackle projects specific to your industry. For instance, if you’re in need of a plumbing partner, pick a team with licensed plumbing designers and master plumbers with expertise in industrial and commercial applications. Or, if you’re in industrial refrigeration, your partner should be experienced with ammonia pipe fabrication and welding per ASME pipe code.

Choose a responsive partner

Your time is valuable, and you have timelines to meet—your pipe fabrication professional should be communicative and flexible to meet your needs. The right partner will respond to questions and requests promptly, transparently, and thoroughly to keep your projects moving efficiently and smoothly.

They’ll also provide all required details and efficiencies upfront to avoid miscommunication’s costly, resource-draining results.

Confirm the pipe fabricator has the capacity for your project

For your project to be finished on time, your pipe fabrication resource will need more than just the right capabilities and certifications. They need the bandwidth and space to accomplish what you need.

As mentioned above, a great partner will be responsive and honest. Simply ask them to provide information about their staff and facility size to assess better whether they will be able to handle your project. If available, browse projects and case studies on the fabricator’s website and social media channels to see if past customers experienced any issues.

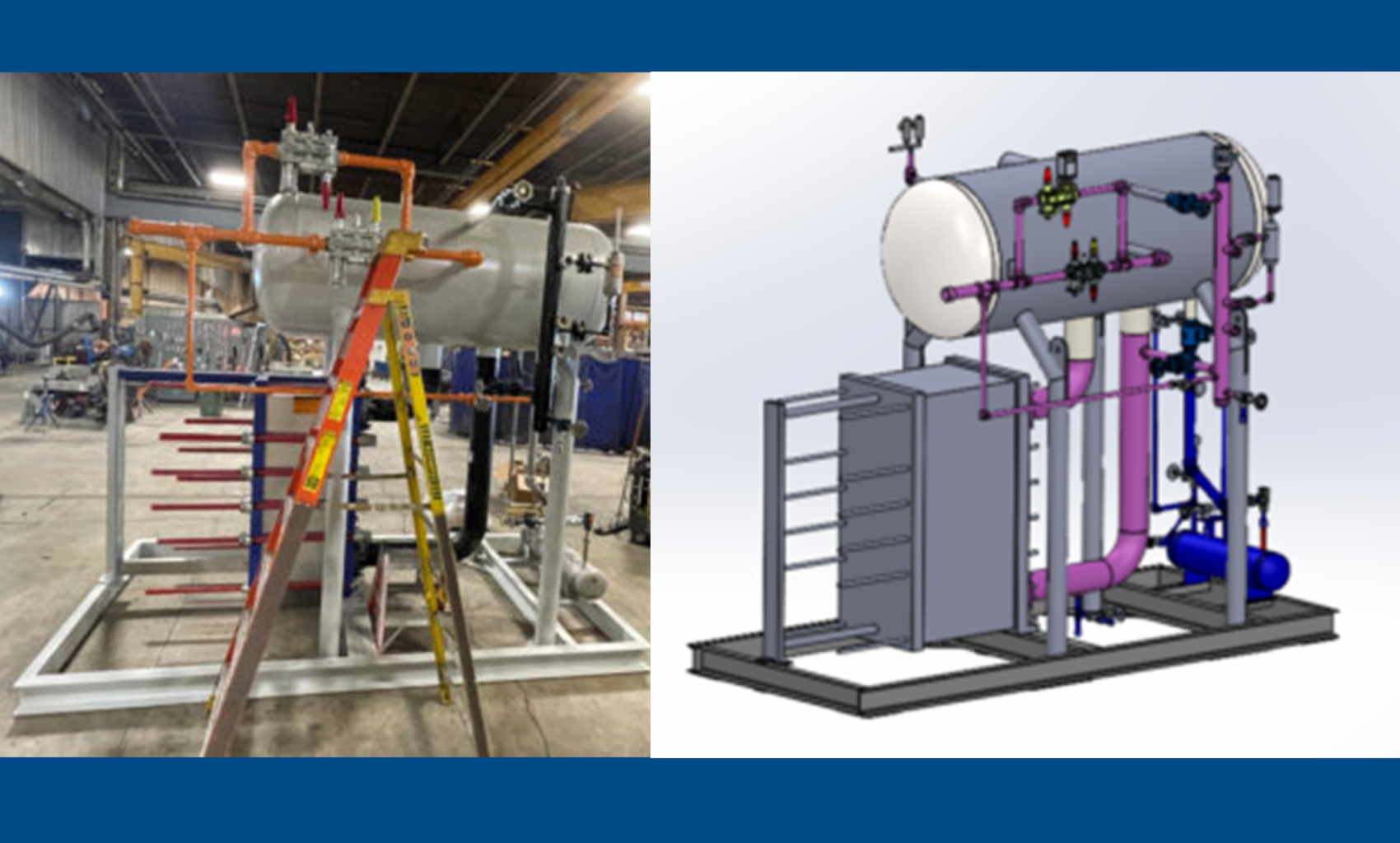

Work with Bassett Mechanical for Custom, Precise, Prefabricated Piping

You’re in luck if you’re looking for a team that checks all the boxes we list above. Bassett Mechanical has extensive piping capabilities in numerous materials and sizes, thicknesses, and complexity. We’re an ASME-certified*, 268,000-square-foot shop with UA-trained professionals who specialize in ASME pressure vessels, modular skid packages, and pipe spool fabrication. We’re committed to your systems’ safety, integrity, and holistic success. Most importantly, we’ll work hard to earn your business for life, just as we’ve been doing for our customers since 1936.

Get in touch with us today to learn more about our industrial pipe fabrication offerings and expertise.

Looking for something else? Learn more about our additional metal fabrication solutions.

*ASME certified shop “U,” “R,” “S,” B31.1, B31.3, B31.5 and 200+ ASME weld certifications in accordance with ASME section IX