Does your Mechanical Contractor have what it takes? There are three things to consider when choosing a Mechanical Contractor: safety, qualifications, and capabilities. To better serve you, we have created this series as a guide to help you identify the right Mechanical Contractors to fit your needs and get the job done right. Follow this series to make sure your Mechanical Contractor has what it takes.

All welds are not created equal…and neither are Mechanical Contractors. It is important to make sure that your Mechanical Contractor performs their welding processes within engineered parameters. Welding codes provide guidelines and procedures used for certifying welders and measuring and testing welds to get your job done right. Doing so guarantees that there is a system in place to control the specific welds needed for your fabrication. You might be surprised to know that it’s not always the base metal that fails. Failure can also be due to poor weld quality making it very important that processes and rigor are followed to protect your people, your facility, and your investment.

THE IMPORTANCE OF WELDING CODES

The importance of welding codes. ASME (American Society of Mechanical Engineers) outlines design and welding requirements for products such as power boilers, pressure vessels, and piping systems. AWS (American Welding Society) outlines design and welding requirements for structural components, frames for skids and supporting structures, and more. These codes provide guidelines for amps, volts (heat), travel speed (duration), pre-heat requirements, and filler metals to be used, in order to achieve the appropriate mechanical properties in a weld.

As part of the ASME code, many products (depending on the size and the scope) are also hydro-tested. Pressure vessels carry a unique concern due to their ability to contain toxic substances or contents under very high pressure. Therefore, pressure vessels must earn their ASME mark by first passing pressure testing (generally 1.3 times the operating pressure). This process includes hold points at different stages throughout fabrication to confirm compliance with each code and WPS (welding procedures specifications). AWS also maintains a list of design requirements, as defined by the engineer of notary, which need to be followed to ensure compliance.

THE IMPORTANCE OF WELDER QUALIFICATIONS

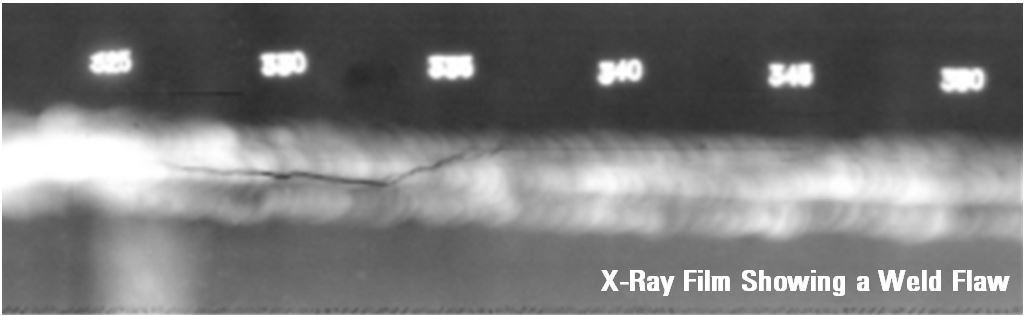

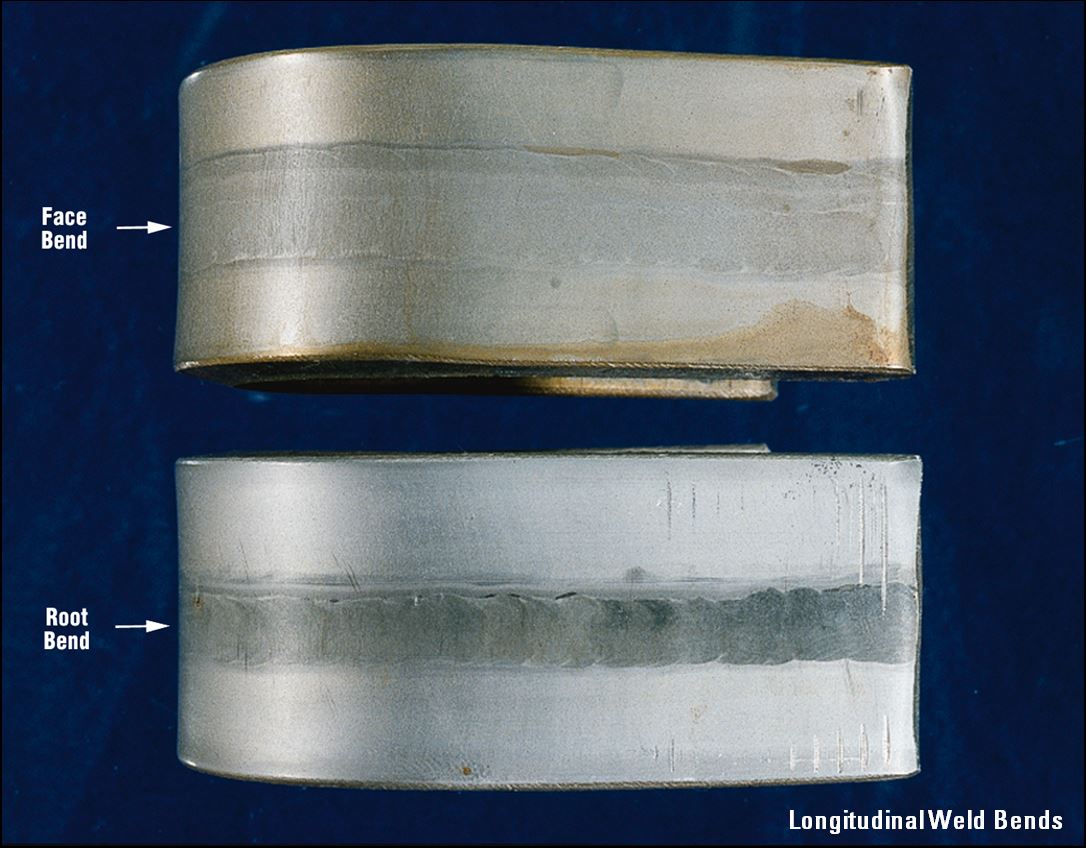

Not only are the processes and products rigorously tested, but so are the welders. ASME certified and qualified welders are physically tested through hands-on welding. They are visually critiqued and their welds are mechanically tested for soundness. While visual and mechanical testing can be done in-house at many facilities, a third-party source is often required for x-ray (radiography) testing and to provide a final volumetric interpretation of pass/fail.

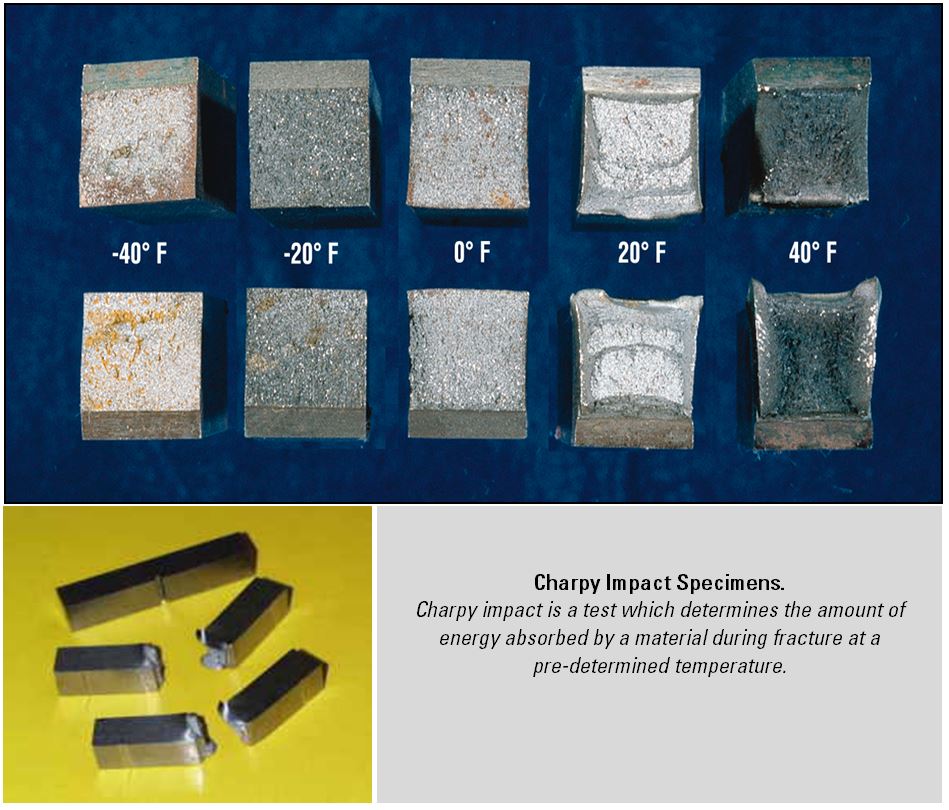

Welder qualification for ASME is based on the type of application for the product being built. This means that there is a variety of unique testing and procedures for products being used for things such as human occupancy, high purity, nuclear, high pressures, low temperatures etc. There is a common minimum standard requirement which is always tested, however, based on the type of process additional testing and criteria are added in order to pass qualification.

AWS has a similar process for qualification based on the use of the product. In this case, the criteria for testing is based on the potential for the product to encounter things like earthquakes (seismic), wind shear, load-bearing, etc.

These codes are put into place to make sure you aren’t putting your operators, end-users, or companies at risk.

HOW SERIOUS CAN A WELD BREAK REALLY BE?

Failures can be as minute as a small crack or drip, or as catastrophic as an explosion or toxic leak. These codes are put into place to make sure you aren’t putting your operators, end-users, or companies at risk. Even if a failure is small, it will directly affect the people on your facility floors exposing them to unsafe conditions and potential for bodily harm.

At their core, ASME and AWS focus on the quality of the product. By choosing a Mechanical Contractor who has these certifications and processes in place, you receive the best overall value and longevity of your investment and are providing your people with the safest possible working environment.

CHOOSING NOT TO USE A CONTRACTOR THAT USES ENGINEERED CODES SUCH AS ASME AND AWS CAN HAVE DISASTROUS CONSEQUENCES.

Without specific procedures, you increase your risk of variability in the weld, and therefore also increase the risk of failure. ASME and AWS procedures have been engineered and proven and give you peace of mind knowing that you are putting your product and your people in the safest possible environment.