In industrial refrigeration, ensuring the longevity and safety of refrigeration vessels is paramount. One of the significant challenges faced in this domain is Stress Corrosion Cracking (SCC), particularly in ammonia refrigeration systems. At Bassett Mechanical, we prioritize the integrity of our systems by implementing Post-Weld Heat Treatment (PWHT) wherever feasible. This article delves into the intricacies of SCC and highlights why PWHT is the best solution to mitigate this issue.

Historical Context of SCC in Ammonia Systems

The phenomenon of stress corrosion cracking in steel exposed to liquefied ammonia was first widely recognized through incidents in industrial refrigeration systems. A pivotal review by A.W. Loginow in 1989, published in the National Board BULLETIN, recapitulated decades of field experience and research, highlighting how SCC was identified as a serious threat to carbon steel vessels operating in dry ammonia environments. These early findings laid the groundwork for today’s design standards and mitigation practices, including PWHT and operational controls to reduce residual stress and oxygen exposure. Understanding this history helps clarify why SCC remains a critical concern in modern ammonia refrigeration systems.

What is Stress Corrosion Cracking (SCC)?

Stress Corrosion Cracking is a metallurgical phenomenon where cracks form and propagate in a metal due to the combined influence of tensile stress and a corrosive environment. In ammonia refrigeration systems, SCC typically occurs in carbon steel vessels under either residual or applied stress in the presence of dry anhydrous ammonia and oxygen. The most susceptible vessels are on the high side of the ammonia system, where non-condensable gases (i.e., air) may accumulate.

Factors Contributing to SCC in Ammonia Systems

Several factors contribute to the occurrence of SCC in ammonia refrigeration vessels:

- Material Susceptibility: Carbon steel, especially those with higher yield strength, is more prone to SCC.

- Stress: Residual stresses from welding or applied stresses during operation can drive crack propagation.

- Chemical Environment: The presence of oxygen and very dry ammonia (less than 100 ppm water) creates a favorable environment for SCC.

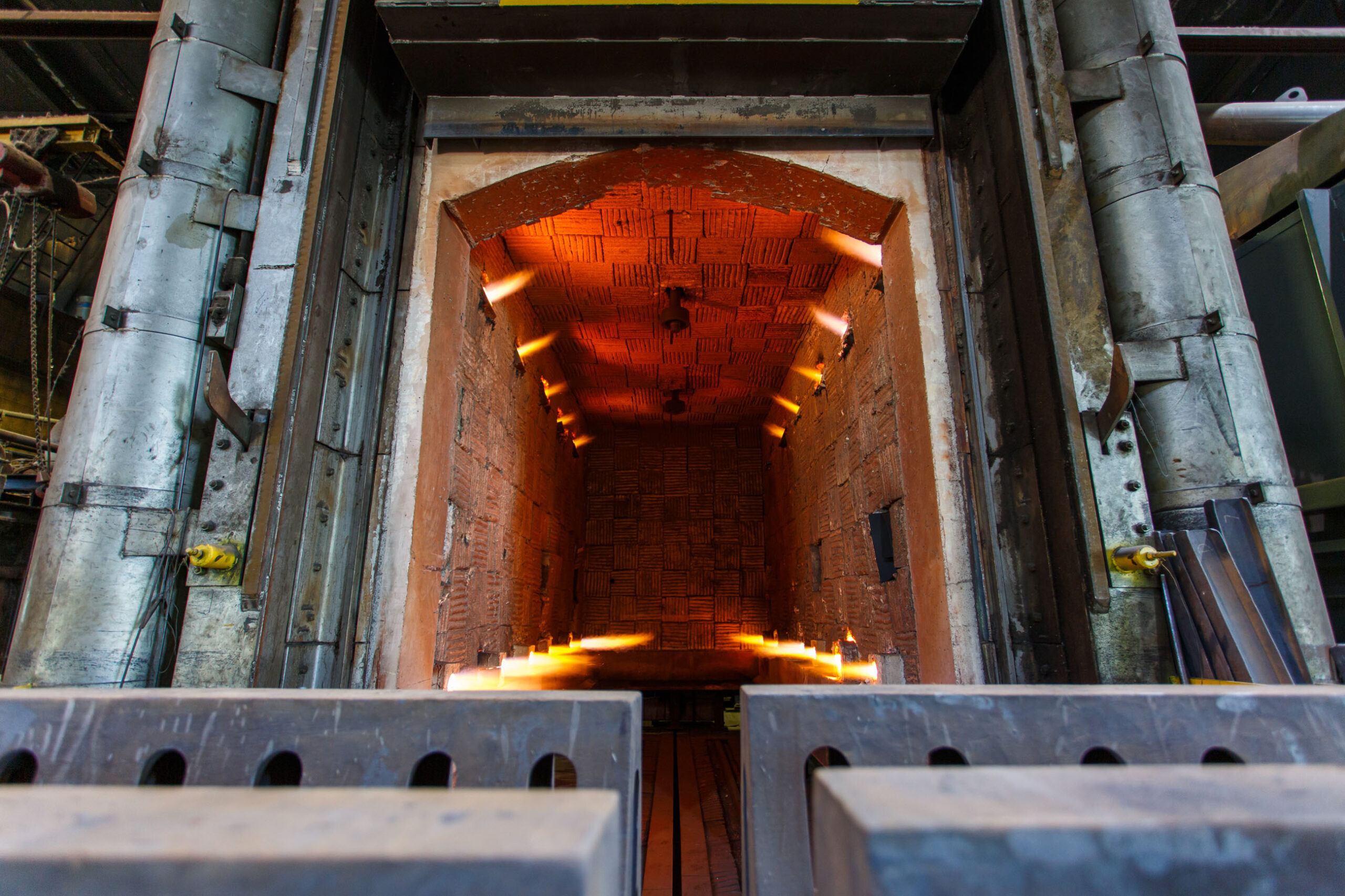

The Role of Post-Weld Heat Treatment (PWHT)

Post-weld heat Treatment is a controlled process where welded materials are reheated to a specific temperature and then cooled slowly. This process helps relieve residual stresses and improve the material’s mechanical properties. For ammonia refrigeration vessels, PWHT offers several benefits:

- Stress Relief: PWHT significantly reduces residual stresses induced during welding, which are primary drivers for SCC.

- Enhanced Toughness and Ductility: The heat treatment process improves the toughness and ductility of the material at lower temperatures, making it less susceptible to cracking, while retaining its mechanical properties (i.e., yield strength).

- Microstructural Stability: PWHT helps achieve a more stable microstructure, reducing the likelihood of crack initiation and propagation.

Design Considerations to Prevent SCC

To minimize the risk of SCC, several design considerations should be considered:

- Material Selection: Use lower-yield-strength carbon steel to reduce the tendency to crack during fabrication and operation. Recommendations include using materials with a minimum yield stress at or below 70 ksi (480 MPa).

- Vessel Construction: To minimize residual stress, we prefer hot-formed heads over cold-formed ones. IIAR requires all Ammonia Refrigeration Vessel heads to be either hot-formed or stress-relieved.

Operational Considerations to Prevent SCC

Proper operational practices are crucial for preventing SCC:

- Purge Air from Ammonia: Remove air and non-condensable gases during initial start-up and continuously during operation using autopurgers.

- Maintain Water Content: Maintain a minimum water content of 0.2% in the ammonia to inhibit SCC. Water acts as an oxygen scavenger, reducing the risk of SCC.

- Avoid Rapid Temperature Changes: Limit the rate of temperature change to minimize thermal stresses that can lead to SCC.

- Inspect Regularly: Follow routine inspection guidelines, including annual visual and independent inspections every five years. High-risk components like transfer vessels and high-pressure receivers should receive more frequent inspections.

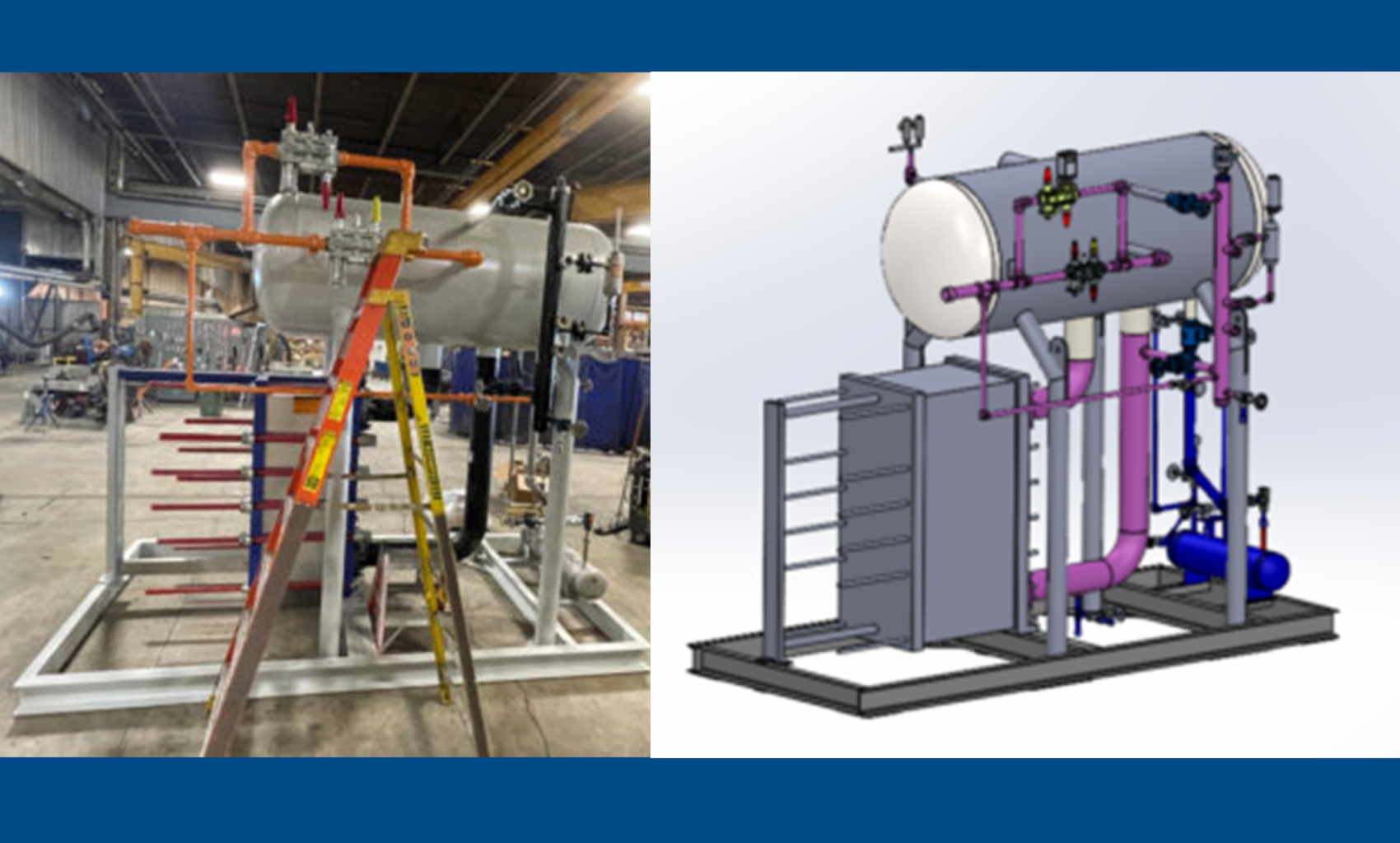

Bassett Mechanical’s Commitment to Quality

At Bassett Mechanical, we understand the critical nature of SCC in ammonia refrigeration systems. Our standard practice is to implement PWHT wherever feasible, ensuring that our refrigeration systems are robust, reliable, and safe. By adhering to stringent quality standards and leveraging advanced metallurgical practices, we deliver ammonia refrigeration systems that stand the test of time.

References

Alexander, V. C., & Laucks, F. M. (2001). Stress corrosion cracking of steels in ammonia. In Proceedings of the 23rd Annual Meeting of the International Institute of Ammonia Refrigeration. Long Beach, CA: IIAR.

Bansch, R. (2007). Stress corrosion cracking in the ammonia refrigeration industry. In Proceedings of the 29th Annual Meeting of the International Institute of Ammonia Refrigeration. Nashville, TN: IIAR.

Industrial Refrigeration Consortium. (2005). Stress corrosion cracking: Prevention. The Cold Front, 5(2), 1-9.

Loginow, A. W. (1989). Stress corrosion cracking of steel in liquefied ammonia service – A recapitulation. National Board BULLETIN, National Board of Boiler and Pressure Vessel Inspectors. Retrieved from https://www.nationalboard.org/index.aspx?pageID=164&ID=182

Reindl, D., & Crement, D. (n.d.). Ammonia-induced stress corrosion cracking in a carbon steel vessel. University of Wisconsin-Madison.

Southwest Research Institute. (1976). Stress corrosion cracking tests of high strength steels in refrigerated ammonia. SRI Project No. 02-4723.