WE LISTEN

Our customer – a medical device company in the Madison, Wisconsin area – had an aging building automation system. They were faced with a choice to either make updates or install a new system. The customer was looking for additional control and consistency with their system to meet the fluctuating temperature and comfortability needs of their employees. The customer’s facilities manager who has been with the company for 35 years saw firsthand the building and its systems go from new to old, and he knew it was time to reach out to us due to our relationship as his HVAC service provider. We introduced him to our controls department and capabilities, and he wanted to proceed with improving the building’s automation system and efficiency throughout the facility.

WE DISCOVER

The nearly 25-year-old, 100,000 square-foot building includes an office and a manufacturing facility with 16 rooftop units (RTU) and multiple variable air volume systems (VAVs). Our team of certified control experts performed a walk-through to gain an understanding of existing on-site conditions and what solutions we could offer to solve some of their immediate and long-term needs. We reviewed the current state of the equipment, pain points, and top priorities for implementing a new system. Due to the type of product being produced in the facility, controlling humidity was recognized as a top priority.

WE LOOK AHEAD

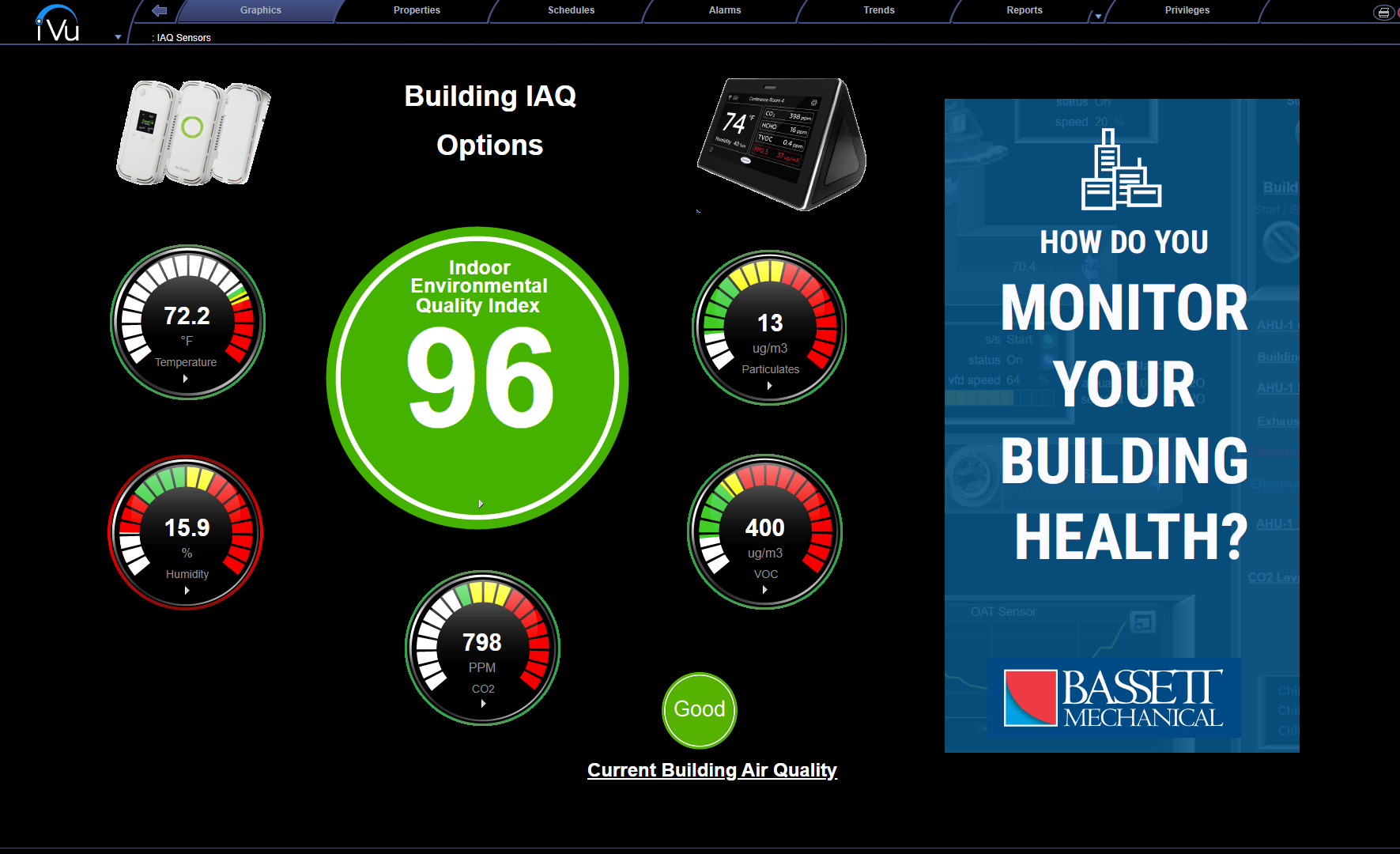

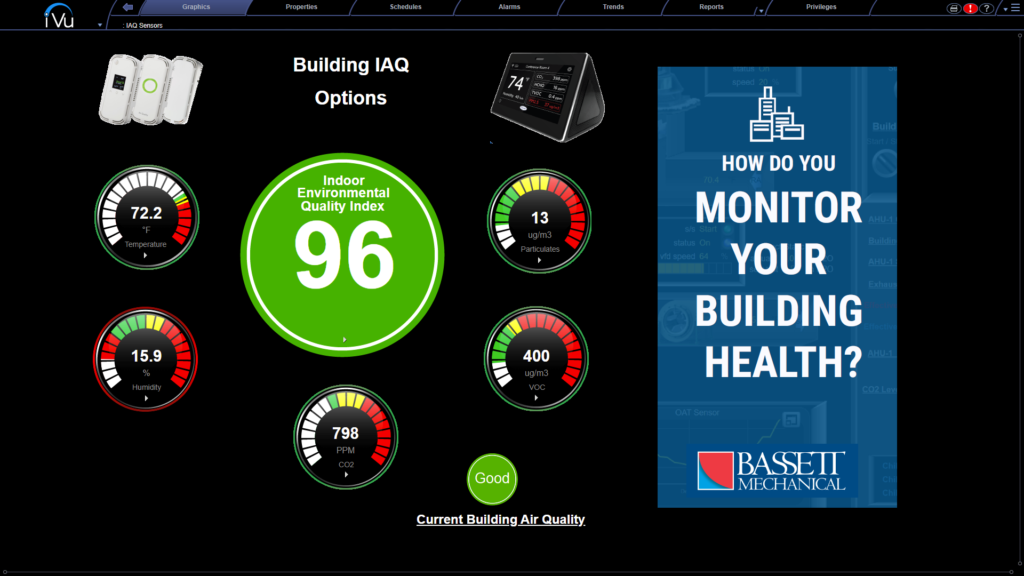

To meet the customer’s needs and budget, our team prepared a phased approach detailing step-by-step solutions and recommendations for updating the system. The proposed solution included an update to the rooftop units and the installation of a Carrier iVu system with multiple building health sensors. This system optimizes the use of the HVAC system to deliver cleaner, safer, more efficient, and more productive indoor environments, and provides an easy way to monitor the building’s health and humidity at the click of a button. The phased approach allows the customer to have a detailed plan of the next steps so they can act diligently when their budget allows.

WE DELIVER COMPLETE SOLUTIONS

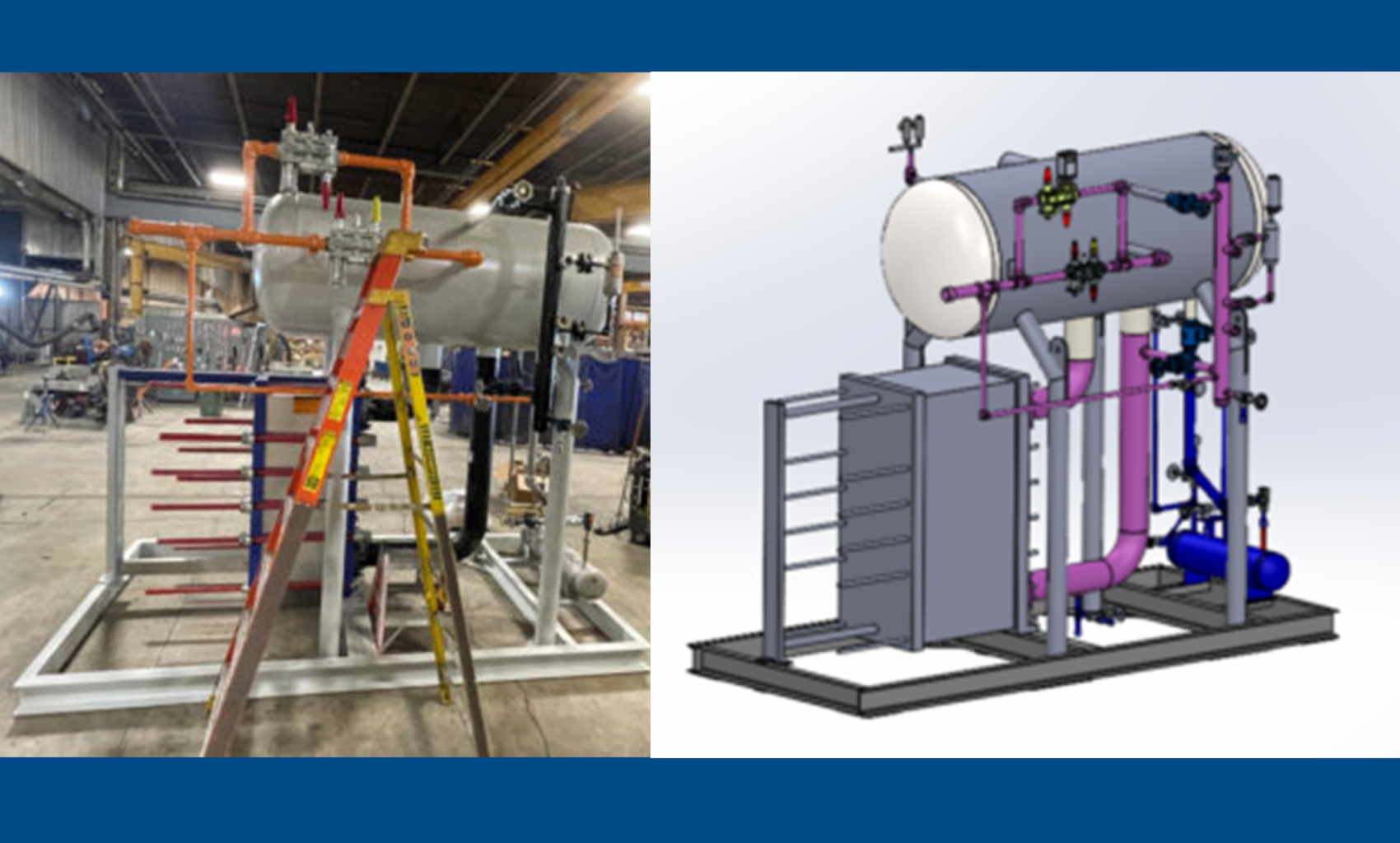

Our full-service solutions on this project included service, HVAC controls, and metal fabrication.

WE ARE CREATING CUSTOMERS FOR LIFE®

With a 10+ year relationship, this customer is truly a “customer for life”. We were chosen for this project based on our long-standing relationship as their HVAC service provider, their experience with our consistently high-quality solutions, and our extensive experience in the HVAC and HVAC Controls industry.

After reviewing our proposal, the customer chose to update 5 of the rooftop units and install an iVu system with building health sensors. Hardware components were replaced, and a new control system was implemented. Installation of the new system was completed without disruption to the customer’s facility or production.

To focus on the customer’s top priority of humidity and building health, our controls team developed uniquely designed graphics for the customer to highlight temperature, humidity, VOCs, CO2, and more. The facilities manager can view the health of the building digitally and make any necessary changes without physically traveling to multiple parts of the building, allowing more control and consistency.

I could not be happier with our new iVu system and building health sensors. With the click of the mouse, I can control our entire building from my computer. The program is user-friendly, and the graphics present an impressive picture of what is going on within different areas of the facility. With these new controls, there’s no doubt that we are significantly cutting down on our energy usage. – Facilities Manager

Upon installation, our controls team provided training for the customer and checked to make sure the system was operating as intended. The customer partnered with us to offer access to their system, allowing our teams to remote into their system at any time, anywhere, to troubleshoot issues.

With the iVu system installed, the customer can expand the system to bring in more equipment as the facility’s needs continue to grow.

Thanks to the close collaboration between Bassett Mechanical’s HVAC engineers and industry experts, we have the advantage of leveraging the knowledge within our team to integrate control systems customized to meet your requirements and anticipate any future needs. Contact our Controls Experts today to help you save energy, provide total comfort, and maximize efficiency.