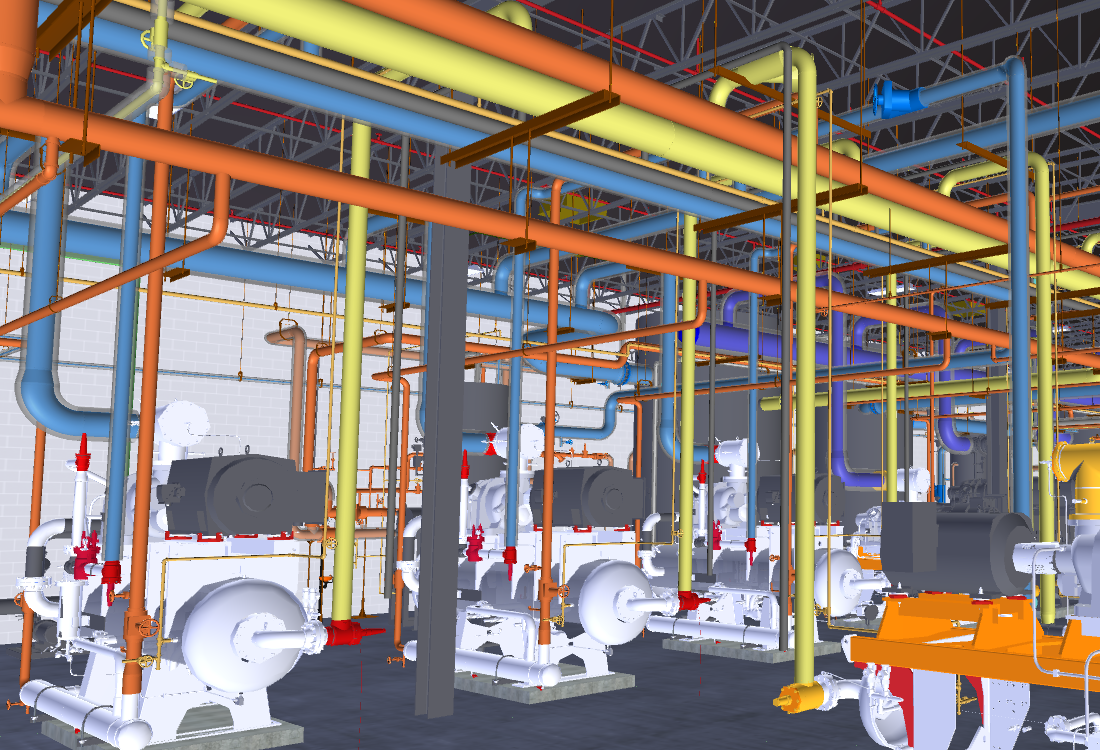

A company’s choice to invest in and expand their virtual design and construction (VDC) capabilities is a significant decision accompanied by many positive impacts for the customer. For Bassett Mechanical, this expansion included adding design resources and purchasing two key pieces of equipment. Both pieces of equipment are essential to the VDC process and improve our ability to design, pre-fabricate, and perform field layout with a great degree of accuracy.

LEICA RTC 360 LASER SCANNER

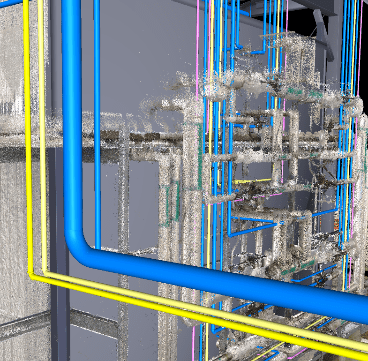

The Leica RTC 360 laser scanner captures existing conditions so that our VDC team can design a mechanical installation within an accurate virtual representation of the space. The laser scanner measures at an impressive rate of 2 million points per second with accuracy of +/- ¼” at 200ft, all in just under 2 minutes per scan.

LEICA ROBOTIC TOTAL STATION (RTS)

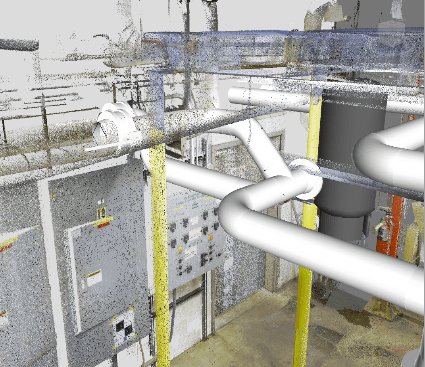

With the Leica Robotic Total Station (RTS), layout points of items such as equipment, supports, and penetrations can be placed in the model by the designer and then exported onto a tablet that technicians use to remotely control the RTS. The VDC Field Technician can then locate the points at the job site for our field crews. The RTS requires only one operator and ensures that the layout onsite is in sync with the model rather than scaling drawings and taking dimensions manually from various points such as column lines on the job site.

Virtual Design and Construction technology is advancing and changing rapidly as more and more contractors and customers recognize the benefits of being able to design, coordinate, and pre-fabricate from the Building Information Model (BIM). Bassett Mechanical is committed to utilizing these cutting-edge technologies in combination with our extensive design and prefabrication capabilities to provide safe and high-quality solutions for our customers.