In our fast-paced world, we are all constantly searching for ways to be more effective and more efficient. It’s natural that we would search for these same qualities in an HVAC, Plumbing, or Industrial Refrigeration provider. Someone who can provide efficient solutions and get us moving on to our next project. While finding a partner who offers a full-service solution could save you time and money in the long run, it is also important to ensure the solution is the most responsible for your needs.

WHAT DOES IT MEAN TO PROVIDE A “RESPONSIBLE SOLUTION”?

When it comes to solutions, you have a lot of options. You can choose the quickest, easiest, or least expensive. You can also choose the most researched, most efficient, best presented, or most unique. How do you know you are making the right choice? A responsible solution should be created with a complete birds-eye view of the entire project from a range of technical perspectives while weighing the upfront costs as well as future costs, and possible risks or challenges to each potential solution. A responsible solution is not a “quick fix”, it is a thorough plan created to best fit the needs of the customer and facility both now and in the future. A provider with your best interest in mind is willing to weigh all the options to set you on a path for success.

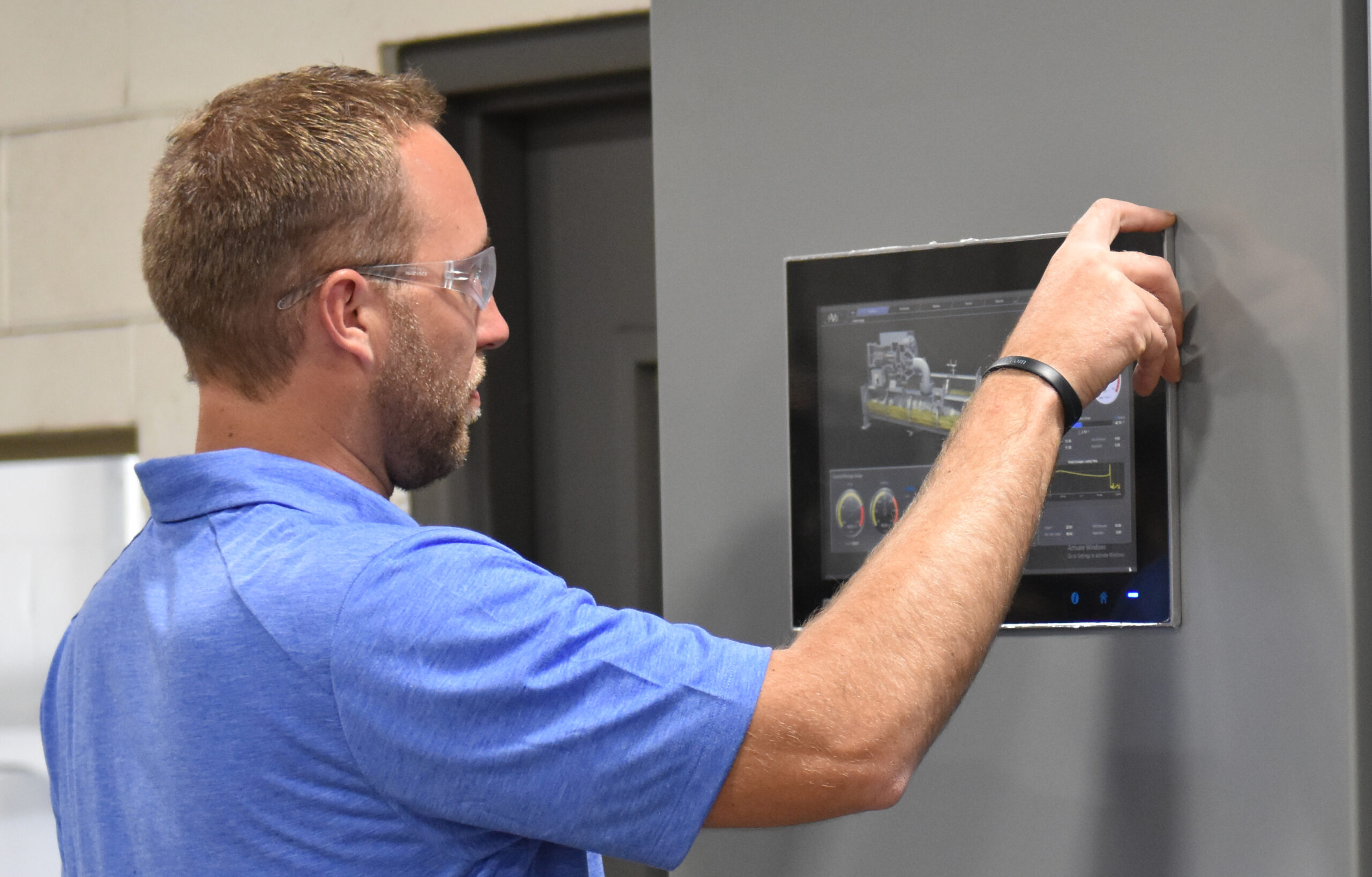

As a key component of our full-service capabilities, Bassett Mechanical’s HVAC Engineering and Design-Build team provides responsible solutions not only for our external customers but also works in tandem with our other various areas of business such as Metal Fabrication, industrial ventilation, process piping, project management, and service. Here are three ways this team commits itself to a responsible full-service solution (and reasons to consider a provider who is keeping your best interests and future in mind):

1. Root Cause Analysis

Part of providing a responsible solution is ensuring that the solution in one area does not cause issues in another. There are many pieces and variables involved in providing the right solution. By solving a problem without looking at all of the other contributing factors, the solution provided could be incomplete, cause complications with another part of the system, end up being costly, or reduce the life of your equipment. Instead of simply correcting an evident symptom, your full-service provider should review the solution from a wide-ranging perspective, determine any underlying root cause, and provide the appropriate solution to correct that root cause. Your facility requires a trusted, strategic, responsible solution that does not temporarily solve a problem but digs into the root of the challenges you are having.

2. Diverse Expertise

Choosing a full-service provider ensures you are receiving not only the necessary expertise when it comes to HVAC design but also a well-rounded and diverse peer analysis of your system. Our HVAC Engineering and Design-Build team possesses a wealth of varied perspectives, education, training, and experiences in different facility types and system designs. Internal experts are called upon to ensure your solution is the most responsible. This cohesive team (with over 120 years of combined experience) offers customers the correct solution, as all of the resources necessary to review the system inside and out are right here, in-house.

3. High-Quality Process

The right provider should have processes in place to ensure the best quality solutions are consistently met. Committing to a documented procedure means there are checks and balances throughout the process. The Bassett Mechanical HVAC engineering process, supported by our quality management system and ISO certification, ensures a high-quality solution with this process:

- Pre-engineering discussion. Prior to beginning any engineering work, it is important to determine the scope from more than one perspective. We require pre-engineering discussions amongst peers to assist in solution and scope determination. These peer discussions provide collaborative input to ensure the proposed solution and costs are the most responsible method to solve the problem.

- Pre-proposal field input. During the proposal process, field experts review and provide insights on the proposal and estimates for constructability, safety, and accessibility. This ensures all walkways, service platforms, and required clearances and distances are maintained and that equipment installations are serviceable, maintainable, and safe.

- Drawing peer review. Each construction drawing set goes through a peer review for a final evaluation. A checklist is completed to ensure that each and every detail is covered and that the drawings and plans are ready for field installation. This touchpoint supports efficient and accurate field installation, ISO procedures, and quality standards.

The goal is to solve more than just the symptom. A quality partner will search for a root cause, understand the scope, and use a variety of internal experts to evaluate the best solution possible. A trusted provider will look at the operation, life cycle, maintenance, safety, performance, and other crucial details and offer a unique, high-quality solution that will fit your needs today and in the future. Is your provider committed to giving you a solution that solves not just your immediate problem, but also fits your overall needs?