Investing in a preventative maintenance agreement with a service provider is an important decision and can make a significant impact on the future of your equipment. By not proactively maintaining your system, the equipment becomes stressed and is subject to inefficiencies, delays, or even potentially full system failure. Preventative maintenance extends the life of your equipment, provides energy efficiencies, and protects your investment.

Investing in a preventative maintenance agreement with a service provider is an important decision and can make a significant impact on the future of your equipment. By not proactively maintaining your system, the equipment becomes stressed and is subject to inefficiencies, delays, or even potentially full system failure. Preventative maintenance extends the life of your equipment, provides energy efficiencies, and protects your investment.

The task of choosing the right provider can seem daunting. What services should I ask for? What are the differences to be aware of? As you lay out the pros and cons, requirements and options, consider a provider who specializes in creating customized maintenance agreements.

“We’ve recently transferred over the maintenance for three facilities to Bassett. I’m happy to say that since Bassett has taken over, our number of issues has decreased. It’s been a good partnership so far.” -Jay L., Madison Kipp Corporation

Choosing a provider who offers guaranteed professional maintenance programs can be a strong distinguisher between the services you are paying for and the services you specifically need for your equipment. Customized maintenance agreements are tailored to your unique system to provide optimal reliability and reduce the building’s overall operating costs. Here are a few reasons why a customized maintenance agreement could be the best fit for your preventative maintenance needs:

- One size fits (most). Purchasing a blanket maintenance agreement means that you are potentially paying for services that are not needed or required. Or even worse, not receiving an important repair or maintenance because your unique equipment requires more than the “cookie cutter” agreement can offer. The end result? Inevitable delays and downtime.

- Priority Emergency Response. Weather can wreak havoc on even the most well-maintained equipment. Having a customized maintenance agreement means that your equipment takes priority during even the hottest or most frigid days when you need help quickly.

- Planned vs. unplanned maintenance costs. Some customized agreements include test and inspect only. During this inspection, technicians perform a basic inspection of equipment to identify potential issues that could cause a breakdown and make sure equipment is running at peak efficiency. Equipment grading can also be accomplished during this time to identify the equipment most likely to require immediate attention. This empowers customers to proactively make scheduled repairs within budget instead of waiting for an unexpected breakdown.

- Guaranteed. A guaranteed professional maintenance program can include full equipment replacement, maintenance, repairs, 24/7 emergency service calls, fixed costs for mechanical equipment, project support, equipment grading, and preferred labor rates. This helps cover costs and minimize your in-house administrative costs associated with processing repair orders and requests.

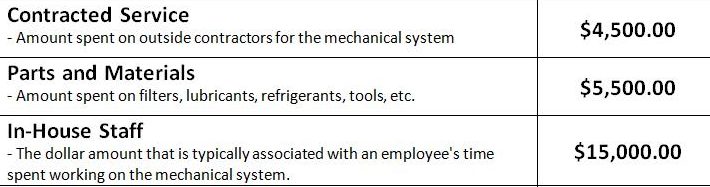

Cost analysis. A cost analysis includes the list of items that are covered under the preventative maintenance agreement. This line item document supplies detail on the cost of the agreement and the costs currently being paid for by the customer prior to the agreement. The analysis is reviewed periodically throughout the course of the agreement to validate the effectiveness of the maintenance program. This puts customers in control so they can strategically account for costs and spend within the parameters of their customized program.

Cost analysis. A cost analysis includes the list of items that are covered under the preventative maintenance agreement. This line item document supplies detail on the cost of the agreement and the costs currently being paid for by the customer prior to the agreement. The analysis is reviewed periodically throughout the course of the agreement to validate the effectiveness of the maintenance program. This puts customers in control so they can strategically account for costs and spend within the parameters of their customized program.- Trusted relationships. Customized programs provide planned work by dedicated technicians who know the facility. During the agreement process, a technician is assigned to each account allowing customers to build long-lasting relationships with their designated technician, who ultimately becomes a part of their extended team.

- Transparency and accountability. At the end of the day, you want to know your provider is doing what they say they will. That commitment to honesty translates into the documentation a service provider can provide as part of a maintenance program. Food and process plants require specific documentation as it relates to refrigerant requirements for EPA audits. Customized agreements give access to an electronic maintenance tracking system (web viewing portal) which provides detailed reports on the maintenance being done on each piece of equipment. Customers can view equipment and repair history at my time, which helps project potential costs or replacements and avoid budgetary surprises.

There are no rules when it comes to hiring a service to provide maintenance on your equipment, but as seen above, there are definite pros and cons. When you are making your list, consider an opportunity to take your proactive preventative maintenance to a new level by choosing a reliable provider who can fine-tune your program to fit exactly what you need to protect your equipment, product, and investment.

Cost analysis. A cost analysis includes the list of items that are covered under the preventative maintenance agreement. This line item document supplies detail on the cost of the agreement and the costs currently being paid for by the customer prior to the agreement. The analysis is reviewed periodically throughout the course of the agreement to validate the effectiveness of the maintenance program. This puts customers in control so they can strategically account for costs and spend within the parameters of their customized program.

Cost analysis. A cost analysis includes the list of items that are covered under the preventative maintenance agreement. This line item document supplies detail on the cost of the agreement and the costs currently being paid for by the customer prior to the agreement. The analysis is reviewed periodically throughout the course of the agreement to validate the effectiveness of the maintenance program. This puts customers in control so they can strategically account for costs and spend within the parameters of their customized program.