At Bassett Mechanical, we pride ourselves on delivering exceptional, innovative solutions tailored to our customers’ needs. Our recent project spotlight highlights our extensive involvement in a facility where we showcased design-build, VDC, PLC controls, and ongoing service solutions, demonstrating our commitment to excellence in every aspect of our work.

WE LISTEN:

A new customer, a leading manufacturer of freeze-dried products including fruits & vegetables, proteins, pet treats, probiotics, enzymes, prepared meals, and candy, sought out Bassett Mechanical after receiving recommendations from various long-time customers. They had a newly constructed, unoccupied building where, on one side, they would produce freeze-dried pet food and, on the other, freeze-dried probiotics. This resulted in the need for thirteen freeze dryers in total. They sought a mechanical contractor to design and install an entire ammonia refrigeration system. We engaged in detailed conversations with the customer to fully understand their needs and expectations, ensuring our solutions would meet their high standards.

WE DISCOVER:

Our initial discovery process revealed the unique challenges of this project. Typically, ammonia piping installations are placed on the roof of a building. However, this job required us to design an indoor system with piping suspended from the roof joists. During the Integrated Project Delivery (IPD) meeting, we leveraged our Virtual Design and Construction (VDC) capabilities to design rack assemblies for the piping. While a few racks in the engine room are standard practice, this project required racking the entire system. This innovative approach streamlined the installation process, improved safety, and enhanced efficiency.

The roof structure needed reinforcement to support the weight of the new system. Collaborating with another company, we ensured that these reinforcements were adequate. Our shop built and insulated 40 ft pipe racks, which were then pressure tested and shipped to the job site for installation. This innovative approach allowed us to keep our field crew size to a minimum, significantly reducing the estimated on-site labor.

WE LOOK AHEAD:

Foresight and planning were crucial in addressing the project’s challenges. Eighty-four rack assemblies were designed by VDC, fabricated, and pressure tested in our shop to be insulated before being shipped to the job site. This pre-fabrication helped control and/or eliminate several variables, including keeping our crew size in the field much smaller than initially estimated. Over 6,000 manhours were transferred from the field to the shop. As a result, the 14-16-person field crew we anticipated was only 10.

We installed and piped 13 freeze dryers, with 4 operating at extremes: negative 70 degrees Fahrenheit temperature! These conditions presented unique challenges, such as thermal contraction and the necessity to adapt the system to function beyond its usual parameters. The extreme cold required us to employ innovative techniques to ensure the system’s reliability and efficiency. Despite these difficulties, our team’s forward-thinking approach and meticulous planning minimized the need for on-site adjustments, ensuring a smooth and efficient installation process. This proactive strategy saved time and resources and demonstrated our commitment to delivering high-quality solutions in the most demanding environments.

We installed and piped 13 freeze dryers, with 4 operating at extremes: negative 70 degrees Fahrenheit temperature! These conditions presented unique challenges, such as thermal contraction and the necessity to adapt the system to function beyond its usual parameters. The extreme cold required us to employ innovative techniques to ensure the system’s reliability and efficiency. Despite these difficulties, our team’s forward-thinking approach and meticulous planning minimized the need for on-site adjustments, ensuring a smooth and efficient installation process. This proactive strategy saved time and resources and demonstrated our commitment to delivering high-quality solutions in the most demanding environments.

The project also involved designing and implementing a custom PLC control system. We installed an Ignition Vision HMI Control panel serving 77 network devices, including 38 evaporators and 57 ammonia sensors. This system provided precise control and monitoring of the refrigeration processes, enhancing the facility’s operational efficiency and reliability.

Additional project facts:

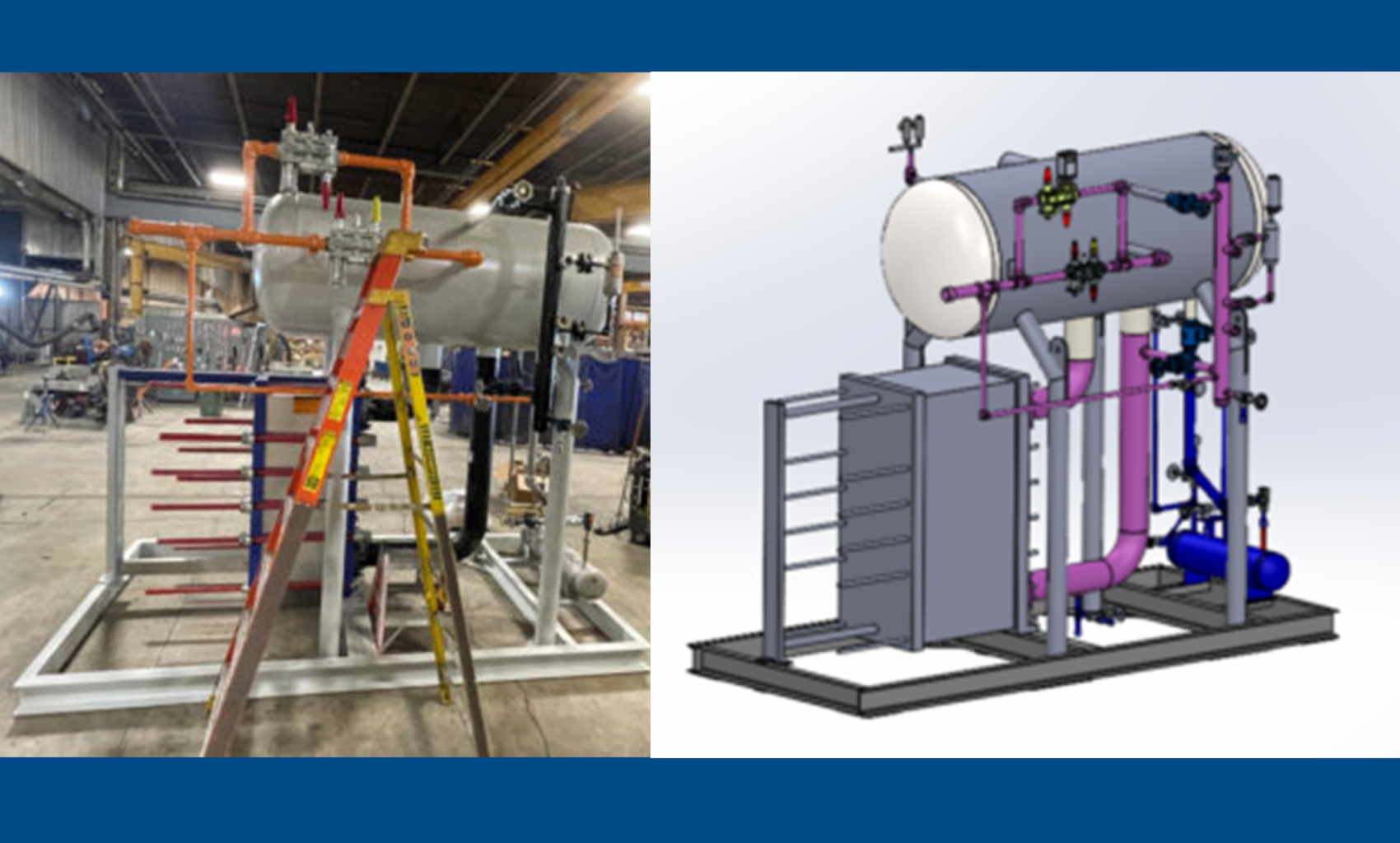

- Fabricated 17 vessels and skid packages

- Shop fabrication hours – 12,800

- Field refrigeration installation hours – 14,750

- VDC/CAD hours – 2,600

WE DELIVER COMPLETE SOLUTIONS:

Bassett Mechanical’s involvement in the facility included the design-build of the ammonia refrigeration system, all required ammonia pressure vessels, a custom PLC controls system, and ongoing refrigeration and HVAC maintenance services. Our comprehensive solutions were tailored to meet the customer’s specific needs, utilizing our advanced VDC capabilities to ensure efficiency and reliability.

Bassett Mechanical’s involvement in the facility included the design-build of the ammonia refrigeration system, all required ammonia pressure vessels, a custom PLC controls system, and ongoing refrigeration and HVAC maintenance services. Our comprehensive solutions were tailored to meet the customer’s specific needs, utilizing our advanced VDC capabilities to ensure efficiency and reliability.

This project required over 30,000 man-hours, with significant portions of the work transferred from the field to our shop, demonstrating our ability to adapt and innovate. The challenges we faced and overcame enhanced our expertise and showcased our determination to deliver excellence in every project.

WE ARE CREATING CUSTOMERS FOR LIFE®

At Bassett Mechanical, we are committed to pushing the boundaries of what is possible in design-build projects, ensuring that our clients receive complete, cutting-edge solutions that exceed their expectations. This project spotlight is a testament to our dedication and expertise in delivering exceptional results.