A structural engineer is vital for a properly designed project. Whether the project is a new building, a renovation to an existing structure, or supporting the ammonia system structure on your rooftop, you’ll want to partner with a company that has an in-house structural engineer on its team.

According to the Institution of Structural Engineers, structural engineers help create record-breaking, beautiful, useful, and sometimes just cool structures – anything from bridges, rollercoasters, and skyscrapers to hospitals, homes, and public artworks. They work as part of a team with architects, builders, and other engineers to ensure structures are strong, stable, and work well for their intended use.

In industrial refrigeration, the safe design of an ammonia refrigeration system includes more than just the pipes that carry the refrigerant to and from the equipment. Structural engineers are crucial to your project team, ensuring your project is and remains structurally sound.

THE IMPORTANCE OF IN-HOUSE STRUCTURAL ENGINEERING FOR INDUSTRIAL REFRIGERATION

Does your industrial refrigeration contractor have in-house structural engineering capabilities? For businesses especially, knowledge is power, and understanding your industrial refrigeration contactor’s qualifications before your project begins can help eliminate delays and safety concerns along with unplanned financial impacts during the most pivotal part of your project.

By having a structural engineer at Bassett Mechanical, we understand and balance a project’s structural requirements, our manufacturing and installation capabilities, and the project’s limitations in the field; we can tailor the design/engineering (and quoting) to support safe structural practices. The customer can also work directly with one company rather than with several entities supporting project timelines and communications efficiency.

“Simply put, many choices in the structural design process – connections, bracing, loading assumptions, etc. – impact the safety, buildability, material selection, and installation of structural projects,” said Vik V., Structural Engineer at Bassett Mechanical.

With a structural engineer, Bassett Mechanical has the capabilities to ensure that our customer’s structure containing critical components, like ammonia, are structurally sound.

SUPPORTING THE DESIGN OF YOUR INDUSTRIAL REFRIGERATION SYSTEMS

When people think about ammonia systems, they usually think about the safe design of the systems, the equipment, and other components, but not necessarily the structure that supports it, which is still a crucial element. With a structural engineer, we’re taking that extra safety step to ensure a system has the support it needs.

During an industrial refrigeration project, a structural engineer can review many aspects of the project. Some of these can include:

- Equipment support structure (condensers, etc.)

- Ladders

- Walkways

- Platforms

- Elements on a roof (i.e., pipe stands)

Without the expertise of a structural engineer, something as simple as pipe stands that hold the ammonia refrigeration pipes on top of a roof can be overlooked. Is everything structurally sound? In the event of high winds, fire, etc., will the stands hold up? The ammonia piping and the welding are governed by ASME pipe code and other governing bodies (IIAR, etc.) that ensure those components are designed and installed to rigorous standards. If your pipe runs and stands are not adequately designed, they can slide or tip over, putting unexpected stress onto the ammonia pipes that could cause failure.

It’s crucial for all those things to be considered for the safety of your facility, equipment, and people.

STRUCTURAL ENGINEERING AND VIRTUAL DESIGN COLLABORATION

Our full-service solutions can safely bring ideas to life through responsible design, custom manufacturing, and service. Customers can benefit from the structural engineering solutions we provide, along with our virtual design and construction (VDC).

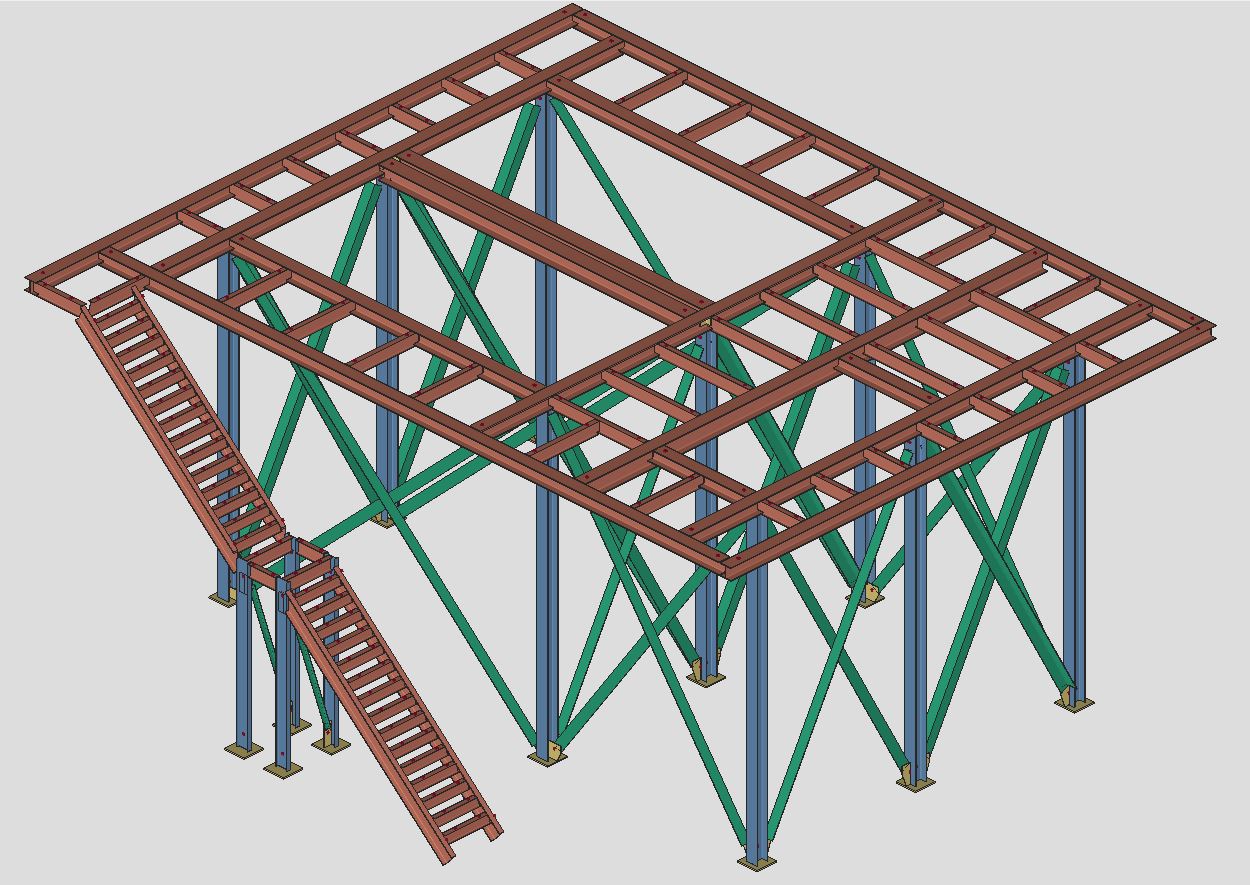

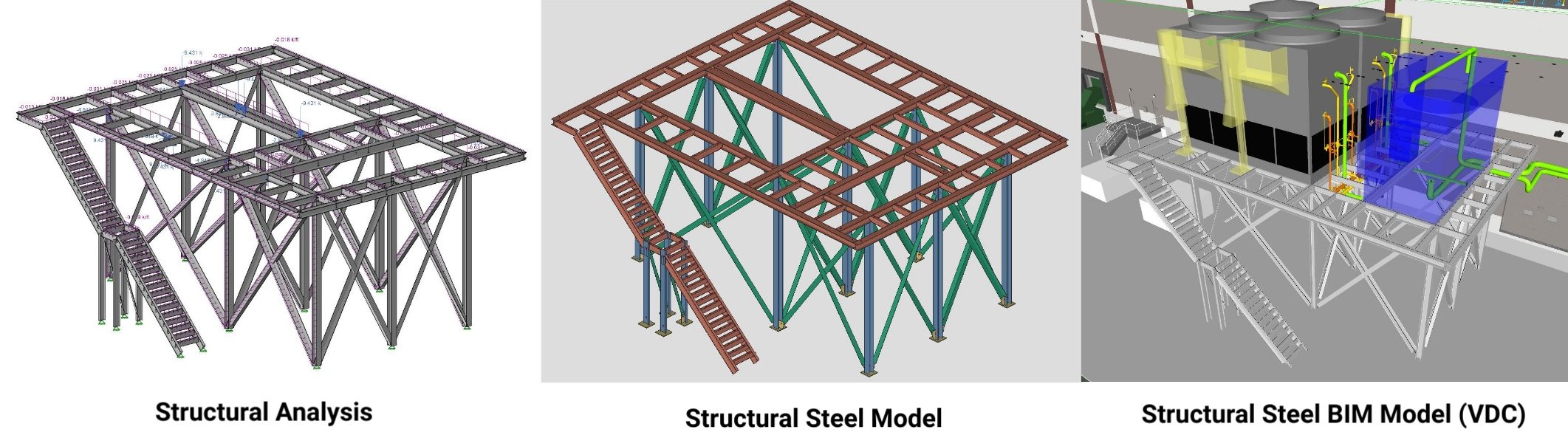

One of our customers was building a new facility, which was going to have an evaporator and cooling tower on a platform next to the building. The piping ran underneath the platform into the building. Due to local jurisdiction requirements, the condenser couldn’t be higher than the building. Instead of outsourcing the design of the platform and all the components, our internal experts joined forces to combine our refrigeration engineering and structural engineering capabilities to provide the customer with a unique solution to fit their needs.

We also take the model used for structural analysis and pair it with our 3D VDC to achieve a more accurate representation of the structure. Designs have been done in 2D, but with VDC modeling, we can consider possible interferences, minimizing the potential of having to fix something in the field. The enhanced capabilities offered through our structural engineering and VDC result in a seamless process for our customers.

Another customer, a cheese manufacturer, was adding a platform with a condenser to an already existing structure. Our team needed to ensure access from the new platform to the existing platforms for people to walk between and to ensure the platforms were at the same height. A ladder on another small platform needed enough clearance to meet OSHA requirements. We used our laser scanning and building information modeling (BIM) capabilities to create a point cloud. A point cloud is a set of accurate, laser-generated data points representing a 3D shape or object. We adjusted the platform for height and position through the point cloud data and checked for interferences before the project was finalized.

An internal structural engineer can provide a lot of value on these projects; by allowing the customer to have one point of contact, we can look at things in real-time for customers, making the process streamlined and efficient.

DELIVERING FULL-SERVICE SOLUTIONS

Bassett Mechanical has more than 85 years of experience designing, fabricating, installing, controlling, and servicing industrial refrigeration systems. We’re proud to have structural engineering capabilities to drive results and value our customers.

For the safety of your facility, your structure, and your people, don’t take a risk on a contractor who can’t provide you with structural engineering guidance from the very beginning to the end of your next project. We offer a structure that meets your unique project requirements and is safe and cost-effective. One more way we continue to become more versatile in support of Creating Customers for Life®.

Learn more about our experts and how we can partner on your next industrial refrigeration project.