REVIT®, a 3D Building Informational Modeling(BIM) tool used by advanced engineering and construction design firms has taken our industry by storm. This software with its ability to develop accurate and error-free building structures can release many of the common pain points that customers may experience during the initial design and construction phase of their project.

PAIN POINT NO. 1: I CAN’T VISUALIZE THE END RESULT

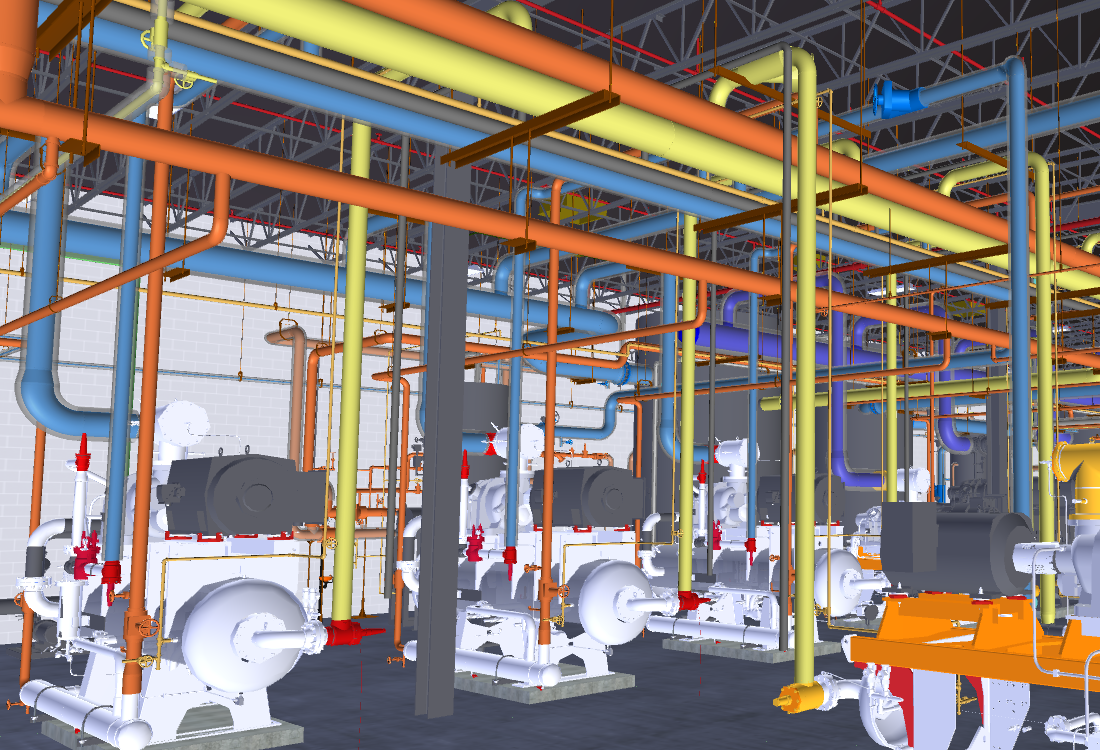

Now you don’t have to. The 3D BIM Modeling component of the software, used in conjunction with 3D pdf’s from Bluebeam, Navisworks and BIM360 TEAM/Glue, allows customers to preview the design of their building and visually anticipate the entire project providing accurate representation before completion of the design. The 3D aspect of the tool can create a design in “real size”. With the ability to “look through ceilings and walls”, customers can now provide feedback during the entire design phase versus during the building phase, when changes can be difficult and costly.

PAIN POINT NO. 2: DESIGN CHANGES TAKE TOO MUCH TIME

Modifications to designs are common and are to be expected. However, communications back and forth can involve change requests, time to implement, and time to review, followed by another phase of adjustments. This process can take a significant amount of time and could eventually lead to delays in the project timeline. Using REVIT® allows for contractors to plan ahead and collaborate with the customer beforehand, providing a reduction in waste and enhanced response time to last-minute changes. The software also has the capability to identify changes and immediately update any related parts in the design making the change process not only quick but also accurate.

PAIN POINT NO. 3: INTERFERENCES AND MISCOMMUNICATIONS BETWEEN ONSITE CONTRACTORS

To keep projects on target, communication between various contractors is important. REVIT® software houses documentation which provides visibility for the many various pieces of the project. 3D modeling is used to highlight any areas that may create conflict allowing all trades to get ahead of areas that have potential to become congested. Coordination of access panels and zones between multiple trades provides visibility and minimizes onsite issues due to miscommunication or lack of knowledge in the overall design. REVIT® software is capable of storing all project data in a single project file which can be edited by multiple users and merged for quick and easy review between all parties on the project. Communication is improved with the ability to share relatively small file sizes utilizing Bluebeam software. This transparency between design and field can eliminate complications when last-minute changes occur during the building phase.

PAIN POINT NO. 4: DESIGN COMPLICATIONS = MAINTENANCE AND REPAIR CHALLENGES

The last thing a customer wants or needs is downtime at their facility. Downtime means product completion is halted, people resources are left waiting, and rooms or spaces become “off-limits”. While limited downtime is necessary and often required for repairs or maintenance, it is cost-effective to minimize this as much as possible. Projects created with REVIT® software have the ability to lay out pipe runs and show valves and shut off points which allows a contractor to easily identify an entry point if a pipe repair or retrofit is required. Maintenance personnel can see the full 3D layout on their tablets onsite and identify exactly where to place an access point. Because of the coordination during the design phase, all trades can ensure that shut-off points and access areas are readily available under the same panel to streamline the process for maintenance personnel and minimize the time spent searching for various valves. This collaborative team approach ensures the customer receives the best possible experience long after the job has been completed.

PAIN POINT NO. 5: PSM AND SAFETY RISKS

Safety of your people and product and compliance with OSHA’s PSM requirements are always top of mind. REVIT®’s ability to store accurate project documentation can assist with your safety and PSM compliance by ensuring all equipment is documented for safety procedures. The software has the capability to store detailed information such as labeling and rating for each component and valve and allows you to “walk through” the entire equipment layout virtually to ensure prevention is accurate.

With seasoned staff proficient in the tool since 2011, we are excited to provide this technology to customers and in doing so enhance the customer’s safety and overall experience. At Bassett Mechanical we are Creating Customers for Life®