Emergency eye wash stations are an essential safety feature in facilities where hazardous chemicals or materials are handled. They provide immediate relief to workers who may have encountered harmful substances and can help prevent serious eye injuries or blindness. This article will discuss the importance of emergency eye wash stations in facilities, what OSHA recommends, and the benefits of inspections and training.

The Importance of Emergency Eye Wash Stations

In facilities where hazardous materials are used or stored, workers are at risk of exposure to these substances. The first 10 to 15 seconds after exposure to a hazardous substance, especially a corrosive substance, are critical. If these substances come into contact with the eyes, they can cause serious injuries such as chemical burns or corneal damage. Quick and effective treatment is essential to prevent permanent damage or vision loss. This is where emergency eye wash stations come into play.

Emergency eye wash stations quickly and efficiently flush the eyes with water or saline solution in an emergency. They can help remove harmful substances and provide immediate relief to the affected person. By providing quick access to these stations, workers can receive the necessary treatment before medical personnel arrives, which can be critical in preventing long-term damage.

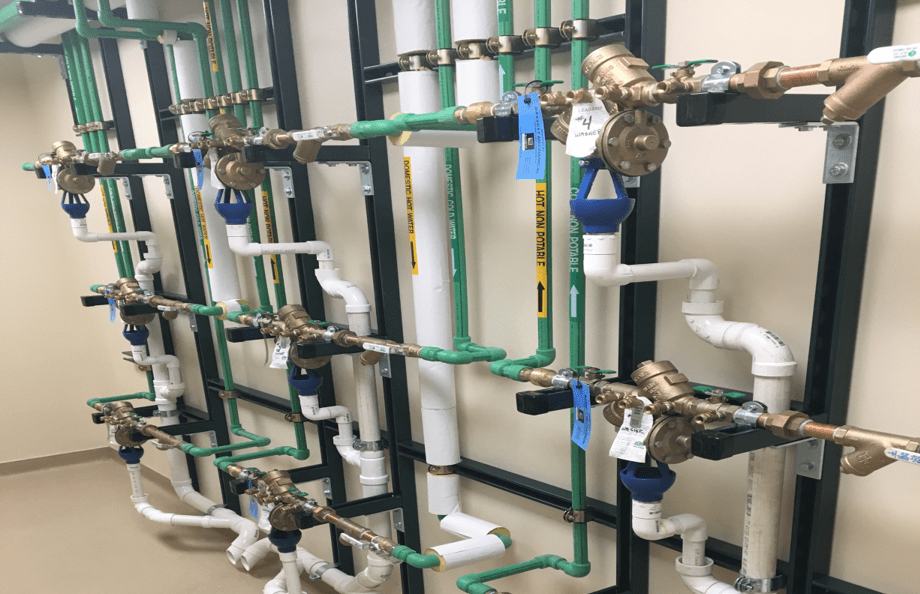

“Many of our customers are required to have emergency eye wash stations due to having harmful chemicals throughout their facility. However, many are unfamiliar with OSHA’s recommendation for minimum flow and water temperature requirements to the emergency eyewash or drench shower,” said Doug V., Plumbing Solutions Manager, Bassett Mechanical.

OSHA Recommendations for Emergency Eye Wash Stations

The Occupational Safety and Health Administration (OSHA) sets standards for using emergency eye wash stations in facilities where hazardous materials are handled.

Which Facilities Should Have Eye Wash Stations?

According to OSHA, emergency eye wash stations should be provided in the following situations:

- Where workers are handling corrosive materials that can cause eye damage.

- Where workers are handling materials that can cause severe eye irritation.

- Where workers are handling materials that can cause serious eye infections.

- Where workers are exposed to airborne particles or chemicals that can cause eye irritation or damage.

Where Should Eye Wash Stations be Located?

OSHA recommends that emergency eye wash stations be within 10 seconds of walking distance or approximately 55 feet of any location where workers may be exposed to hazardous materials. They should also be marked with signage that is visible from a distance and easily accessible.

Eye Wash Station Requirements: Water Flow, Temperature, and More

OSHA and ANSI Z358.1 also set guidelines for facility eyewash stations and showers. Eye wash stations should deliver at least 0.4 gallons per minute of tepid water between 60 and 100 degrees Fahrenheit (15.5 – 37.7 Celsius) for at least 15 minutes. An eyewash drench shower would increase the gallons per minute (GPM) requirement to 20 gallons per minute of tepid water. They should also provide a continuous water flow and be activated in one second or less. In addition, eye wash stations should be inspected and maintained regularly to ensure they are in proper working order.

Learn how to protect your plumbing water supply with backflow prevention testing.

Non-Compliance Examples

Ryan M, Director of PSM Services at Bassett Mechanical, says the most common situation of non-compliance is due to the need for more stations, either inside or directly outside the machinery room of an ammonia refrigeration system, as required by IIAR standards. “Sometimes it is very tricky to install stations outside the machinery room in compliance with the ANSI or IIAR requirements because of stairs or steps for egress out of the machinery room, or the only potential location is outside the building, causing freezing concerns in cold winter conditions, or due to traffic concerns potentially damaging the eyewash/safety shower. Additionally, lack of inspections or materials blocking safe access to an eye wash/safety shower station in an emergency is also often a compliance concern.”

Inspections & Training for Eye Wash Stations

Eyewashes and showers are vital pieces of emergency equipment that need regular maintenance and inspection to keep workers safe. Employees should be trained on the proper use and care of eyewash stations. Having a safety plan that covers the locations of eyewash stations can prove to be vital during an emergency.

According to ANSI/ISEA Z358. 1-2014, plumbed emergency eyewash and eye/face wash stations should be visually inspected and activated weekly. This activation ensures that nothing is blocking the flow of the flushing fluid and eliminates any chance of contamination from stagnant water. It’s also recommended that a comprehensive annual inspection of the facility takes place to evaluate modified workspaces, assess new hazards introduced into the area, and identify fixtures needing repair or replacement.

Stay Compliant with Your Eyewash Stations

Emergency eye wash stations are an essential safety feature in facilities where hazardous materials are handled. They provide quick and effective treatment to workers who may have encountered harmful substances and can help prevent serious eye injuries or blindness. By following OSHA’s guidelines for using emergency eye wash stations, facilities can ensure that their workers are protected from the risks associated with handling hazardous materials.

Many of our associates sit on boards and committees for industry-leading organizations, directly impacting and establishing best practices. For more information on emergency eye wash stations, contact our plumbing experts or email us at info@bassettmechanical.com.

Learn more about our industrial and commercial plumbing services.