Plumbing systems are essential to any building’s infrastructure, ensuring safe and efficient water distribution for various purposes. Cross-connection surveys play a crucial role in identifying and preventing risks, safeguarding public health, and maintaining the integrity of water supply systems.

Local municipalities have cross-connection compliance programs for commercial and industrial facilities and send letters to local property owners. You may have received a letter as a property owner, and now you’re wondering what to do next.

Why am I getting this cross-connection survey notice?

All public water providers must meet rigid requirements established by state and federal agencies to ensure the safety of the public water supply. To protect the public water supply system, the Wisconsin Department of Natural Resources requires municipalities to enforce cross-connection backflow compliance of Commercial, Industrial, and Public Authority properties every 2 years to ensure the safety of your water supply.

What is a cross-connection?

A cross connection is defined as a connection or potential connection between any part of a water supply system and another environment containing substances in a manner that, under any circumstance, would allow the substances to enter the water supply system by means of back siphonage or back pressure.

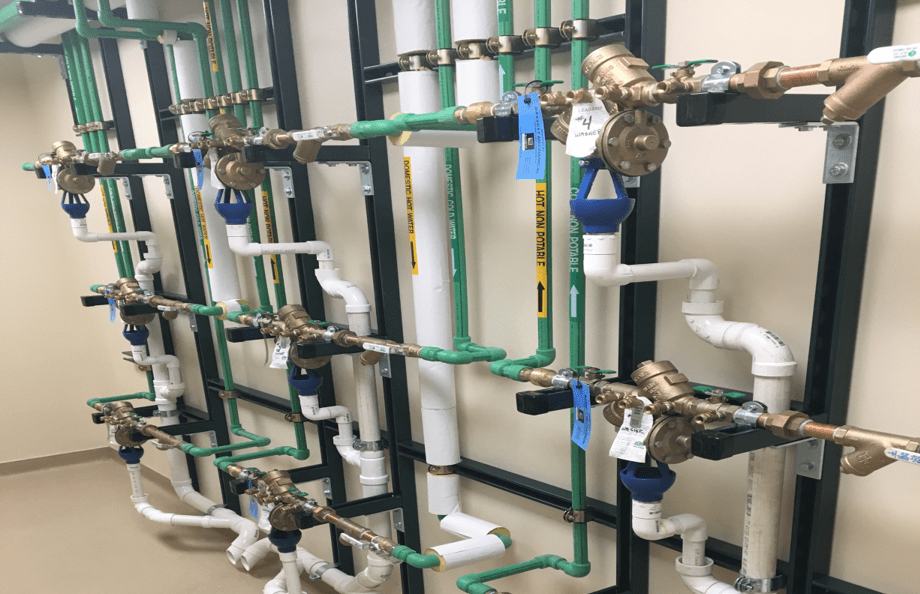

A cross-connection survey is an inspection of the water system piping in a building or property, starting at the water meter and ending at the last free-flowing tap.

What am I required to do?

You must hire a Master Plumber (of your choice) within 30 days of receipt of this letter to have your building(s) inspected for compliance.

How can Bassett Mechanical help with your cross-connection survey?

Survey Inspection and Report Completed by Bassett Mechanical

Cross-connection surveys involve a multi-step process that requires expertise and thorough analysis:

- Site Assessment: Bassett plumbers inspect the building’s plumbing layout and identify potential sources of cross-connection. These sources could include irrigation systems, fire sprinklers, industrial equipment, host stations, foot foamers, battery fill stations, etc.

- Risk Evaluation: Each identified cross-connection is evaluated based on its potential to cause contamination. High-risk connections, such as those with direct chemical access, receive immediate attention.

- Backflow Prevention Measures: Depending on the level of risk, appropriate backflow prevention devices are selected and installed. These devices ensure that water flows in one direction, preventing the backflow of contaminants.

- Documentation: Comprehensive records of survey findings, risk assessments, and corrective actions are maintained and submitted to the state. These records are essential for compliance and serve as references for future inspections.

Another way to stay compliant is by integrating your cross-connection surveys into your maintenance agreement. It’s a proactive approach that offers peace of mind and tangible benefits for your organization and the communities you serve.

The Importance of Cross-Connection Surveys

The integrity of a potable water supply system is a critical aspect of public health and safety. Cross-connection surveys play an indispensable role in maintaining this integrity by identifying and addressing potential contamination risks.

With Bassett Mechanical’s plumbing expertise, we can provide the knowledge, expertise, and solutions you need to help ensure you comply with all local and state requirements.