With its warm, bright sun and clear blue skies, summertime brings a frenzy of water-related activities to keep us cool. From drinking lemonade in the shade to filling up the swimming pool and turning on the sprinkler, it’s clear that a safe and readily available water supply is in high demand. But safe and accessible water is vital for more than just summer fun; it is also critical to our public health, whether used for drinking, domestic use, food production, or recreational purposes. Clean drinking water is something we often take for granted. With backflow prevention testing, you can do your part to protect your facility, your people, and your community and keep your organization compliant with water regulations.

WHAT IS BACKFLOW?

Backflow occurs when non-potable water (water not of drinking quality) or other liquids flow into the piping of the public water system or cross into the building’s drinking water system. There have been many cases over the years where water supply systems in North America were compromised, resulting in severe contamination of potable water.

There are two common causes of backflow in a commercial property:

- Back siphonage – Backflow can be due to back siphonage or reduced pressure in the water distribution system. Back siphonage may occur due to water main breaks, water pump failure, or the drawdown of the firewater supply.

- Backpressure – Backflow can also be due to backpressure or increased pressure from a non-potable water source. Backpressure may be caused by heaters, coolers, boilers, manufacturing systems, or waste disposal.

IMPORTANCE OF BACKFLOW PREVENTION DEVICES

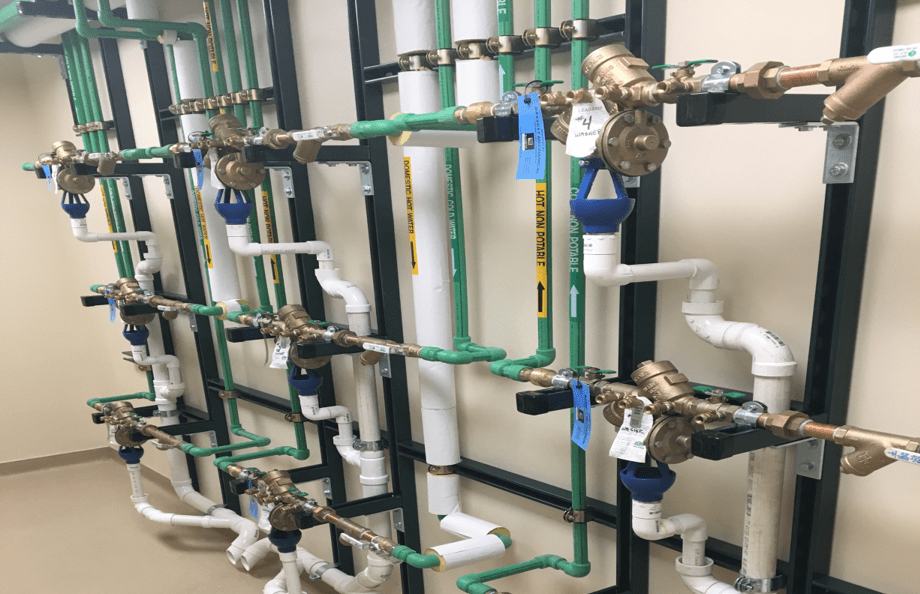

A backflow preventer is an essential part of your plumbing system. The device is installed to prevent drinking water from being contaminated by other sources due to backflow, making it so water can only flow in one direction. This effectively keeps the potable water safe and allows any systematic issues that may occur to be handled without causing a public health and safety issue.

Your backflow preventer device is required to be registered through the state of Wisconsin. To ensure a backflow preventer continues to work as intended, it must be tested annually.

Most common industries with backflow preventers:

- Hospitals and health care facilities

- School districts

- Manufacturing, commercial, and industrial

MANDATORY INSPECTION OF YOUR BACKFLOW PREVENTERS

Compliance and safety are two of the most valuable and necessary components of any successful business. That’s what our team will provide with our backflow prevention testing solutions, giving you peace of mind knowing your systems, facility, and people are well taken care of. We are fully certified to install, repair, replace, and test commercial and industrial backflow preventers in Wisconsin. Our goal is to make testing as simple and hassle-free as possible.

Here’s what you can expect during testing from our licensed plumbers:

Test and maintain backflow prevention devices:

Testing will be performed by a certified, licensed plumber that can immediately perform repairs in the event of failures. They will temporarily shut off the water to perform the testing of the valves. The numbers from the test will be recorded, documented by Bassett Mechanical, and sent to the state of Wisconsin on your behalf. Detailed record-keeping of this information is vital for your maintenance department as well as audits of your facility.

Install and repair backflow prevention devices:

If your backflow prevention device fails, our technicians can typically fix it on the spot preventing the facility from unwanted downtime. Our team stocks our service vehicles with commonly used parts to make these installations quick and painless; a relief for customers who tell us this solution makes us stand out above the crowd.

Detailed tracking and mapping of backflow preventers:

We maintain a detailed inventory of installed backflow prevention devices for maintenance agreement customers. This documentation is important for the facility’s maintenance team and the tester.

Record keeping and scheduling:

After a thorough system audit, we will submit test results to the state of Wisconsin. We keep this document in our records as well, so they are easily accessible. We can develop a customized testing schedule based on your facility, equipment, and compliance needs. Our program keeps you in compliance with annual backflow testing requirements and eliminates late testing. We proactively track, schedule, and perform needed services to maintain your water systems, so you never have to worry.

ADDING BACKFLOW INSPECTIONS INTO YOUR MAINTENANCE AGREEMENT

To streamline the process, we can make backflow prevention testing part of your annual HVAC/Plumbing maintenance agreement. It’s powerful to consolidate your preventative maintenance needs with one company that knows your facility best. Our team of licensed plumbing designers, master plumbers, and skilled tradespeople have the experience and capabilities to handle all your plumbing needs – providing you with the full-service, high-quality solutions your company deserves.

LET OUR PLUMBING EXPERTS PROVIDE PEACE OF MIND

With Bassett Mechanical, you can rest assured that your water is safe for you, your staff, and your customers. Our team understands how crucial it is to prevent your water from cross-contamination, and your safety is our top priority.

So, the next time you get out the garden hose to water your flowers or turn on the kitchen faucet to enjoy a cold glass of water on a hot day, don’t forget the team of experts working alongside companies like you to make safe, clean water possible.

Are you interested in learning more about the overall health of your plumbing system? Visit our educational series on mitigation strategies that support plumbing health.